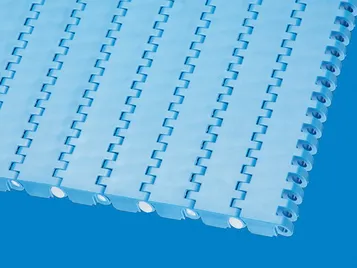

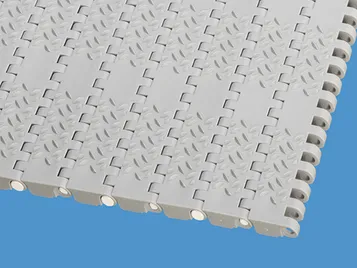

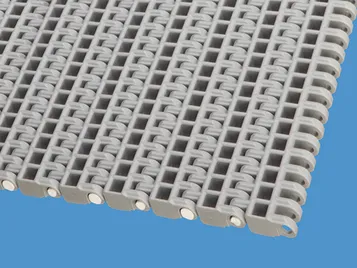

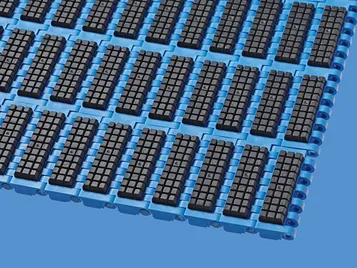

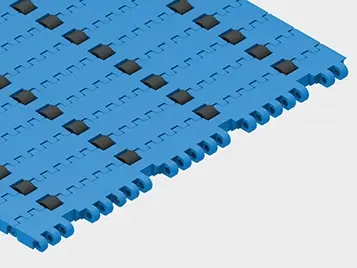

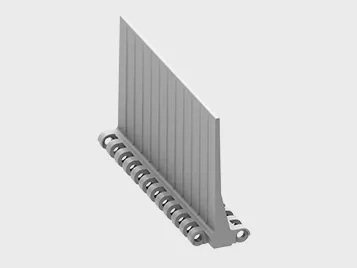

Design characteristics Series 8

- Closed hinge design provides high belt pull capacity

- Rigid module design makes belt suitable for long conveyors

- Robust design guarantees superior durability

- Closed solid edge design

- Flame retardant version available

(PXX-HC – in line with DiN EN 13501-1)

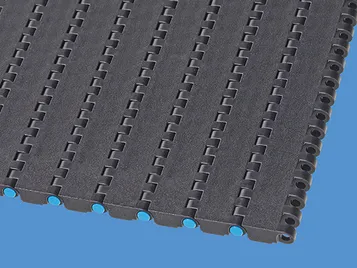

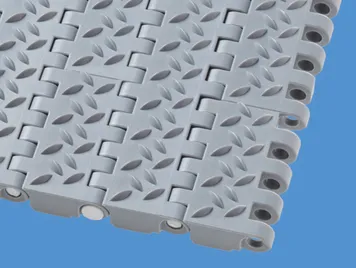

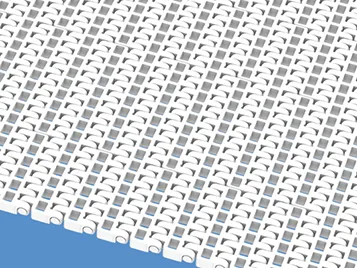

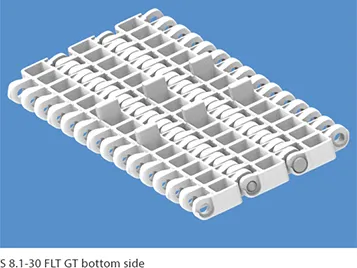

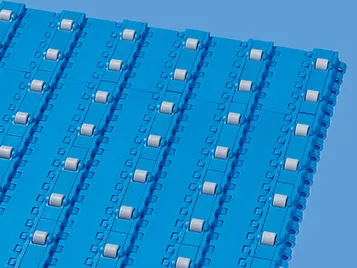

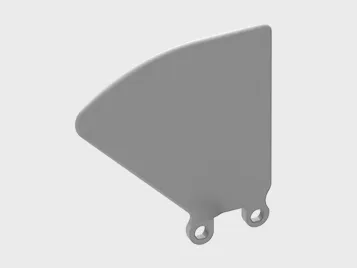

Design characteristics Series 8.1

Designed for further improvements on noise reduction.

- The underside of the belt has an improved contact surface area with the slide bars

- An optimized module and hinge shape allows quiet transition between the slide bars and when entering and leaving the slider bed

Series 8 and Series 8.1 are driven by the same sprockets.

Series 8 and Series 8.1 can be combined and they can use the same range of accessories.