The right solution for any curve

Siegling Prolink spiral belts easily handle extreme temperatures, heavy loads, moisture or tight radii.

.webp)

Spiral conveyors require exceptional conveyor belts. In cooling, freezing, fermenting or drying applications, our modular plastic belts are hygienic, reliable and durable solutions.

Planning a new project or seeking to upgrade your existing spirals? Our belting experts are happy to help.

.webp)

Spiral belts are primarily used in food processing. But other industries requiring reliable conveying in curves under challenging conditions deploy them too.

Hattesen’s Konfektfabrik produces hand-made, vegan, allergen-free licorice with natural flavors on the Danish island of Ærø.

Hattesen chose our Prolink series 18 in spiral towers to dry the sensitive licorice squares:

🔹 Gentle conveying and a sturdy surface with 44% open area

🔹 Efficient drying – 160 m belt length on just a 7 m² surface

🔹 Easy-to-clean design – hygienic, practical to clean, no residues

🔹 Intermittent operation possible – the spiral stops every 6 hours for rotation

The results: Even drying, seamless product release and a belt that (even months later) looks as good as new.

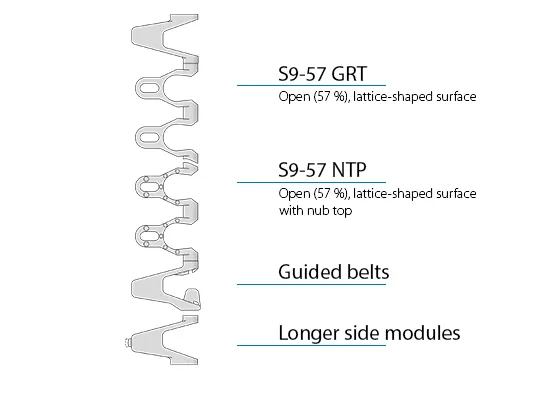

Why series 9 makes a difference to your project:

🔹 It’s a flexible option on straight and curved sections

🔹 With a 57% open area, it offers superb airflow

🔹 It’s robustly designed with stainless steel pins for heavy loads

🔹 It’s reliable and a clip-free splice means smooth operation

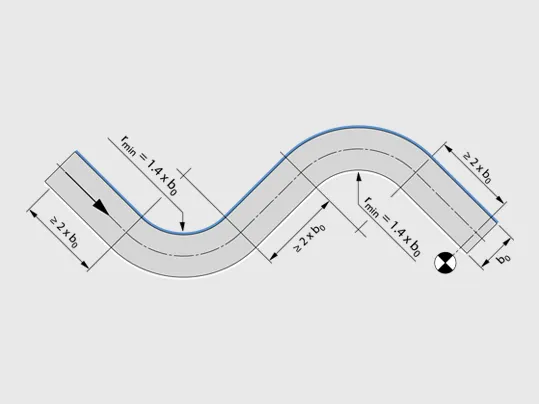

✓ Custom-fit curves for any conveyor

Sophisticated side modules mean our spiral belts adapt precisely to spirals’ inner radius – even where space is tight. Series like Prolink 9.1 enable collapse factors of 1.3 to 2.9 – for compact spiral towers and efficient usage of space.

✓ Robust, hygienic, durable

With their stainless steel pins, exceptional lateral stiffness and easy-to-clean surfaces, our belts are ideal for challenging environments. They comply with challenging international FDA, EU and MHLW Japan hygiene requirements.

✓ Broad range of types

Our portfolio of series S5, S9, S9.1, S11 and S18 offers belts that are open or closed, have a friction lining or a continuous surface. A choice of pitches (25/50 mm), open areas of up to 57%, guided variants and ball-bearing modules mean enormous flexibility for your processes.

✓ For greater tensile force and curve handling

Our combination belts marry superb tensile strength with excellent curve handling – making them ideal for challenging applications. →Find out more

| Series | S5 / S5 ST | S9 | S9.1 | S11 | S18 |

| Pitch [mm] | 25 | 50 | 50 | 25 | 25.4 |

| Open [%] | 33–45 | 57 | 57 | 33–45 | 44 |

| Tensile force POM [N] | 1800/2100 | 2800 | 2800 | 2100 | 2500 |

| Tensile force PA [N] | 1440/1680 | 2241 | – | 1680 | 2040 |

| Material | POM/PP/PE/PA | POM/PP/PE/PA | POM-CR | POM/PP/PA | POM/PP/PA |

| Hinge pin | Stainless steel | Stainless steel | Stainless steel Ø6 | Plastic (PBT Ø 5 mm) | Plastic (Ø 4.2 mm) |

| minimum width [mm] | 100 / 175 (ST) | 100 | 350 | 175 | 149.4 |

| Temp. [°C] | -30 to +100 | -30 to +100 | -45 to +90 | -30 to +100 | -30 to +100 |

.webp)

The Prolink series 5 is the versatile plastic modular belt for curved and straight conveyors in hygiene-critical applications:

- Open area of up to 45% for excellent airflow

- Optionally with Friction Top, Nub Top pattern

- Ball-bearing modules (BT) available for special applications that require low friction coefficients

- Guided and ST variants for greater tensile loads

- Stainless steel hinge pins for smooth tracking.

to excerpt series 5

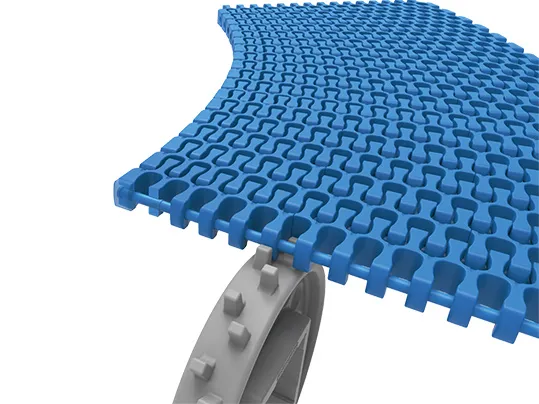

Series 9 belts stand apart for their superior tensile force in curves and inherently stable and hygienic designs. Therefore, they are ideal for demanding applications such as cooling, fermentation and freezing:

- Hard-wearing stainless steel pins affixed to side modules minimize width tolerances in fluctuating temperatures

- Very good belt guidance even with big distances between support strips

- Very strong and wearproof – no abrasion unlike steel belts

-FDA and EU compliant, flame retardant on request (UL-94, V2)

- Quick fitting, easy maintenance, long service lives

to excerpt series 9

.webp)

Forbo’s series 9.1 is a very compact spiral belt for conveyors with cage drives:

- 13 variants for each belt width thanks to combinable side modules

- Smooth tracking thanks to precise radius adjustment

- Footprint up to 48% lower

- Stainless steel pins for heavy loads and easy maintenance

For more, see the flyer on Series 9.1

The Prolink series 11 is a lightweight plastic modular belt for very tight curve radii:

- Curve radii from 1.4 times the belt width

- Up to 45% open area for cooling and drainage

- Plastic pins to save weight

- Friction Top variants available for more grip

to excerpt series 11

Forbo’s series 18 is a very high-performance plastic modular belt for curved and straight conveyors:

- Superior tensile force of up to 1600 N – ideal for tight radii and constant operation

- With a 44 % open area for good airflow and easy cleaning

- Wearproof PLX hinge pins mean stability even in wet applications

- Easy to fit, particularly to existing conveyors

to excerpt series 18

to the series 18 flyer