Tangential Belts

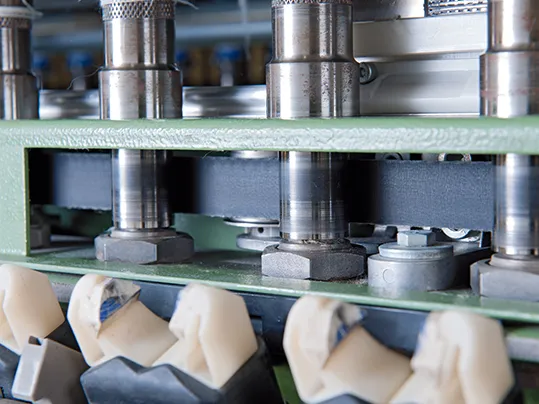

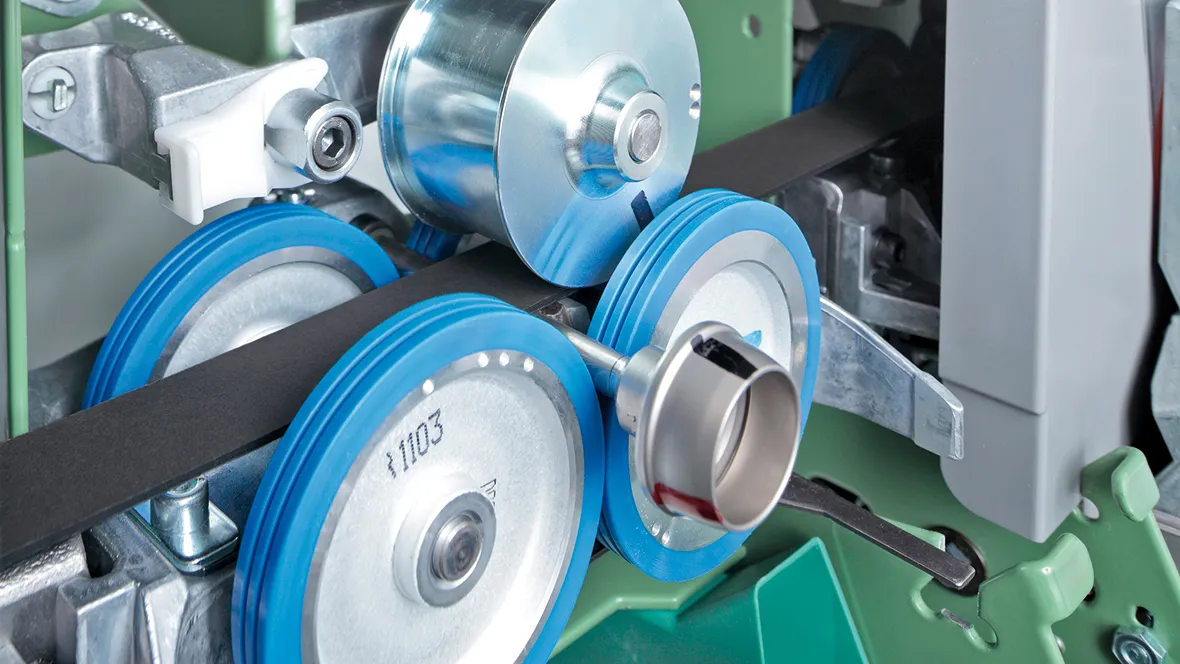

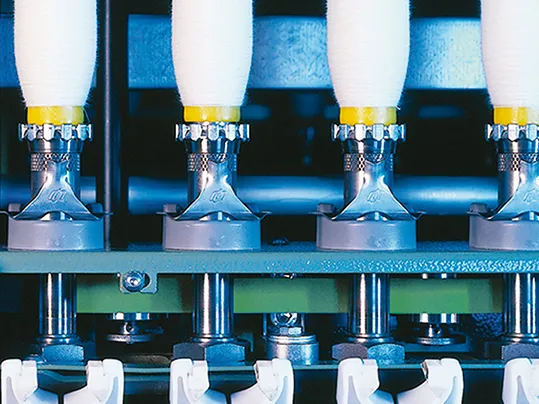

Siegling Extremultus tangential belts are designed for various yarn manufacturing processes and different drive geometries. They play a key role in ensuring that the quality of the yarn is consistent and production is efficient thanks to:

Siegling Extremultus tangential belts are supplied in rolls, prepared for splicing or have already been fabricated. Our methods allow consistent and reliable splices to be made efficiently while the belts are on the machine.

Standard coating combinations

| GG | = | elastomer G underside and top face |

| EU | = | polyurethane underside, fabric top face |