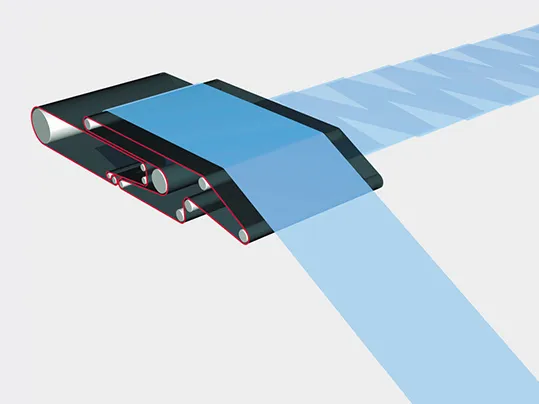

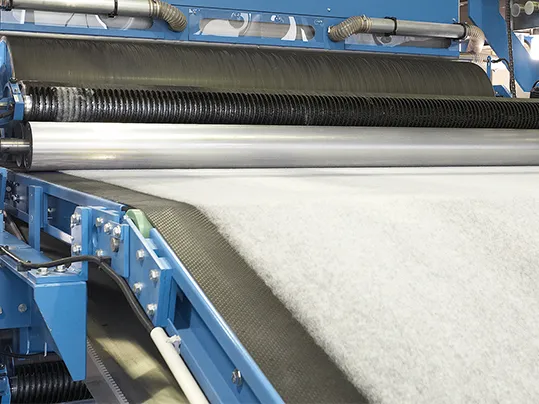

Example: Nonwoven belts in cross-lappers

The delivery of the web with almost no relative motion from the reciprocating movement in the cross lapper and a defined laying pattern with a clean edge – even at high laying speeds – are decisive for the quality of your production. It is also necessary to deal with vital system conditions such as air currents and production characteristics specific to the nonwoven being manufactured. The lower web ply on the lattice apron may not be pressed together and the edges should be flush.