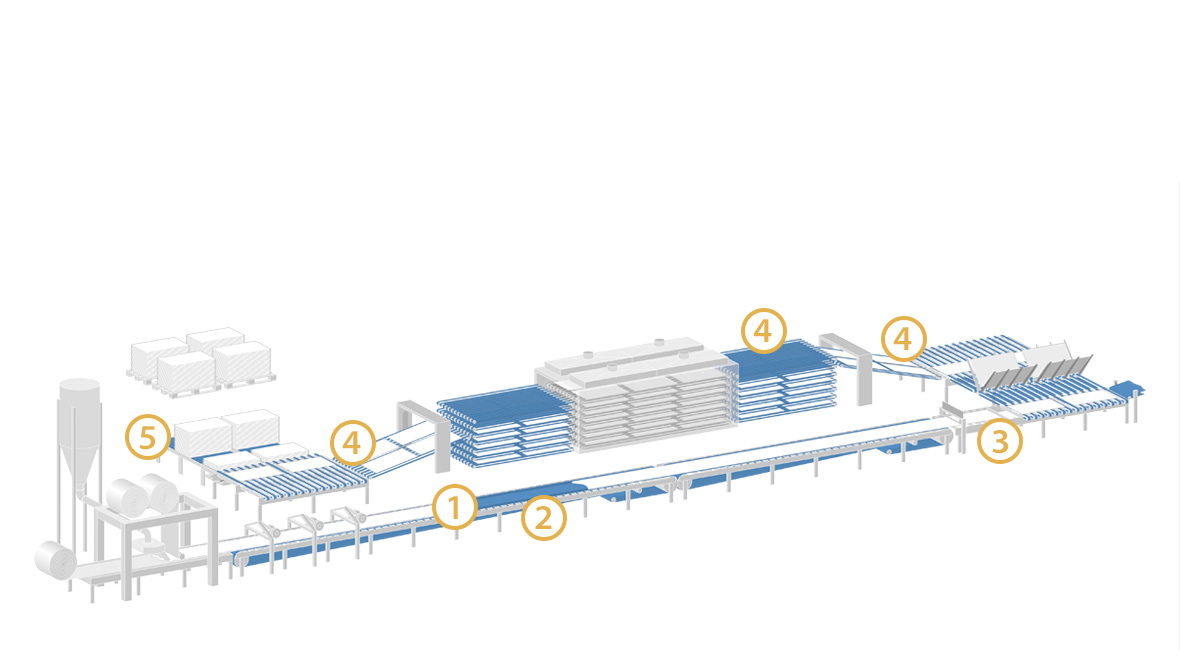

Gypsum Board Production Process

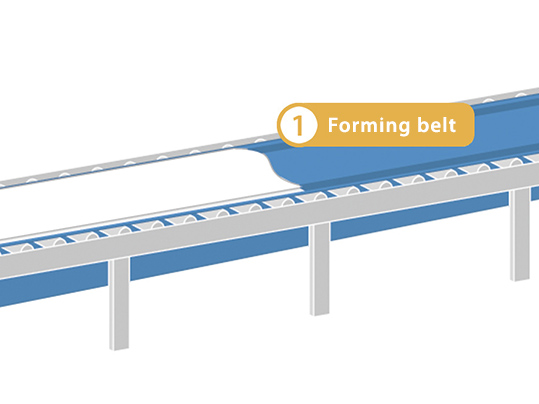

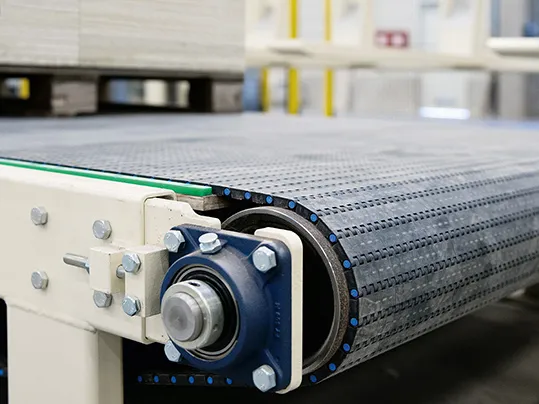

The forming belt is the most sensitive but equally most important component in the entire production process. It both starts and lies at the heart of the production process. The wet gypsum mixture is formed and hardened on it as a flat endless sheet between two layers of heavyweight paper.

Technical Requirements of the belts

To manufacture high-quality plasterboard, the surface quality of the belt has to be superb, its thickness across its entire width, length and splice precise, it needs to track absolutely straight and have a low friction coefficient. These superior belts stand apart for their long service lives but consistently retain the above-mentioned characteristics at the same time. Should minor damage to the belt’s surface occur, it needs to be put it right quickly, easily and efficiently.

Our Solution

Forbo Movement Systems E 20/2 V28/V28 MT/MT grey forming belt is an excellent solution with an outstanding track record worldwide. A double-ply high-tech fabric tension member made of extremely robust and special exceptionally laterally stiff polyester fabric with low elongation makes the forming belt an innovative option. The maintenance-free belt is successfully ousting the thick rubber and PVC belts frequently used in the past.

Characteristics, Functions and Benefits

The PVC belt is 9 mm thick and in addition to its exemplary tracking capabilities and highly accurate thickness tolerance, it’s also very hard wearing and laterally stiff. The belt complies with all requirements. Thanks to its physical characteristics, it can be fitted to virtually any machinery without requiring many modifications in just two days, even if the conveyor was originally conceived for rubber belts.

Other Information

Forbo Movement Systems also offers factory acceptance inspection of the plasterboard forming belts before delivery. Each belt also comes with its own test certificate and a file with handling, cleaning, repair instructions etc. And it goes without saying that we’ll train staff after a new belt has been fitted. Forbo Movement Systems experts can then answer any questions on the spot about operating the belt. A repair set to get rid of any minor surface faults rounds out the portfolio.

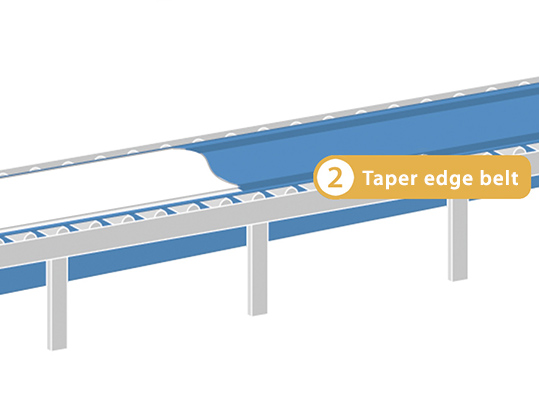

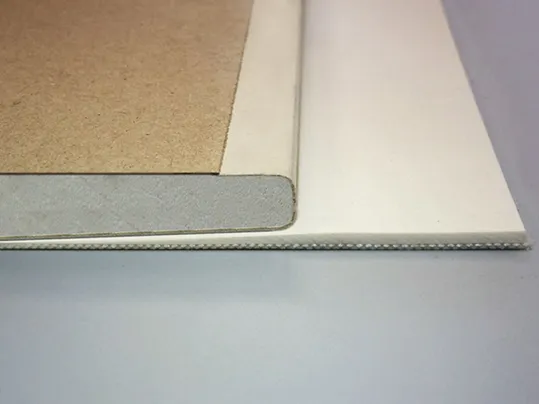

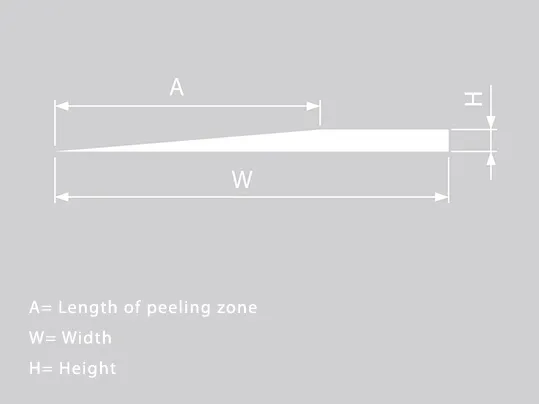

Taper edge belts form the edge shape of certain plasterboards so that these can subsequently be filled on construction sites. They are placed onto the forming belt on both edges of the panels. Taper edge belts are available in virtually all shapes.

Technical Requirements

The shape of taper edge belts should of course match the customer’s production portfolio. Depending on the panel type made, they need to be integrated into the process and removed again without requiring any extra tools. In this case, flexibility and speed have top priority.

The undersides of the taper edge belts should be as soft as possible so that they don’t damage the forming belt underneath. Even if they have long service lives, it’s imperative that taper edge belts maintain their dimensions and don’t elongate.

Our Solution

With total thickness of 2 mm, the fabric-reinforced Siegling Transilon E 6/1 V1/V14 MT-NA white is perfect for these process requirements and guarantees the flexibility required. The belts lie completely flat and keep their shape superbly.

A soft underside of Forbo Movement Systems’ taper edge belts has a fabric that protects the surface of the forming belt to extend its service life. The reinforced belts don’t elongate and can be made endless thanks to straightforward splicing technology.

Other Information

In addition to personal support from experienced specialists, Forbo Movement Systems’ global service network also offers powerful tools so that customers can weld belt ends together themselves.

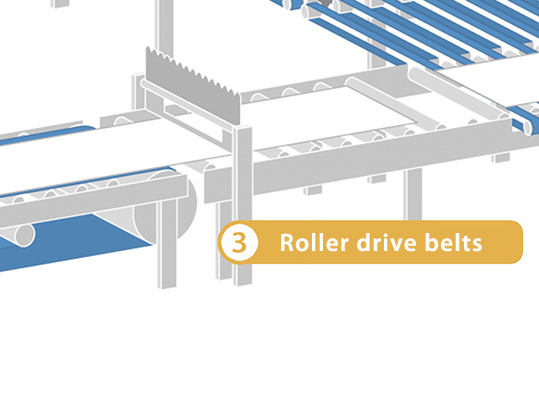

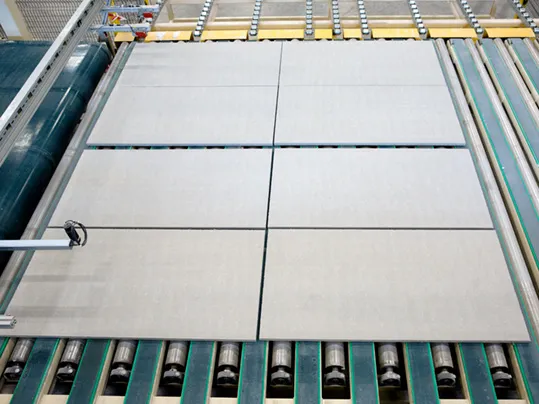

Board conveying is inconceivable without roller drive conveyors. At this step of the process, the roller drive belts have to be fast, reliable and efficient.

Technical Requirements

Here, it’s crucial that the drive component is reliable and maintenance-free in terms of material flow and board conveying despite the high speeds involved.

Our Solution

We’ve developed a range of roller drive belts especially for this application. The combination of tension member and coating gives these belts their special characteristics tailored to the conveyor type and application. As the coating material, highly elastic elastomer or polyurethane ensure seamless and dependable power transmission.

The belts offer unbeatable advantages: durable underside with constant grip; constant tension regardless of temperature and climate (aramide and polyester line); superior flexibility but superb strength at the same time; low power losses due to less creep and little downtime due to fast fitting. All these advantages guarantee long service lives but economical and maintenance-free belts.

Other Information

In addition to personal support from experienced specialists, Forbo Movement Systems’ global service network also offers powerful tools such as the innovative, air-cooled heating clamp from the BlizzardTM line.

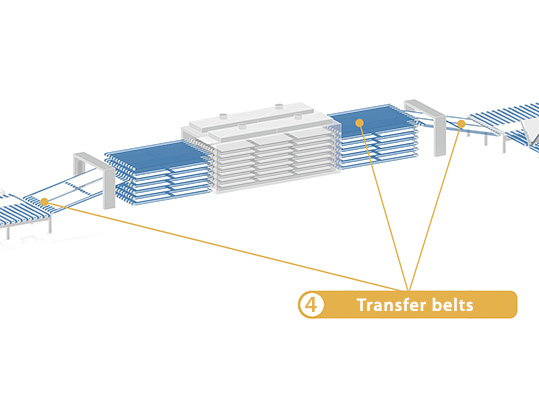

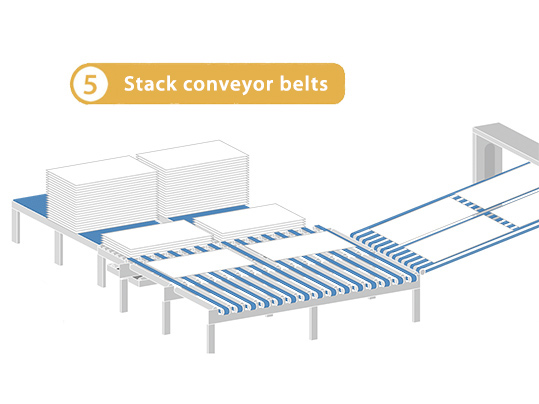

Transfer belts move panels, but can also be used in various processes such as cross conveying, board flippers, dryer in-feed and out-feed sections, stacking and warehousing. They usually run in parallel in a set.

Technical Requirements

Whether the plasterboards are conveyed horizontally or diagonally, the belt’s top face must be able to guarantee reliable, non-slip conveying, especially in the wet section in front of the dryer channel. The belts must be able to position the panels exactly without them slipping.

Our Solution

Forbo Movement Systems offers perfect belts for this challenging task. The types of surface, e.g. with suitable patterns, play a key role in conveying the panels reliably. As a result, unnecessary waste is avoided due to the panels slipping. The surface of the top face means the panels are positioned exactly and the edges protected.

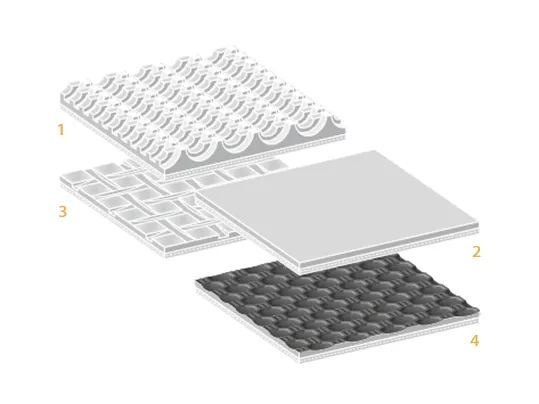

1 - AR = Rough-top

2 - MT = Matt

3 - SG = Lattice

4 - STR = Normal texture

The products’ durability and energy saved due to their ability to run over small return diameters make the process even more economical. Their low weight makes the belts easy to handle and commission. The also operate very quietly so ensure people-friendly working conditions.

| The Characteristics | The Advantages |

| Low elongation | Short take-up ranges, economical |

| Lengthways flexibility | Small return diameters, energy saving |

| Dimensional stability | Reliable and maintenance-free |

| Low noise operation | People-friendly working conditions |

| Durability | Economical operation |

| Compact design | Easy to handle and commission, cost-saving design |

Other Information

Forbo Movement Systems’ global service network offers experts as well as tools and equipment. The type of splice, fitting location (in the workshop or on-site) and last but not least the belt width determine which tool is suitable for the fitting job concerned. As a result, fast, easy and efficient fitting and other services can be carried out by the customer’s own personnel.

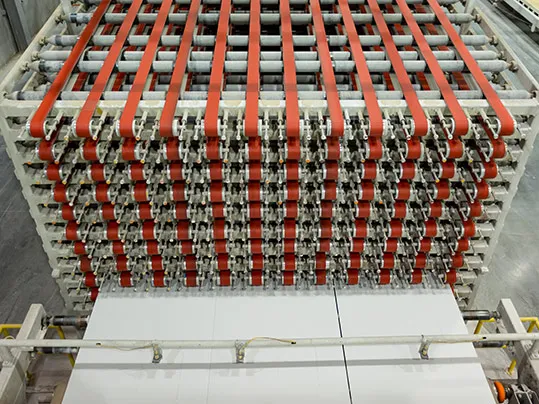

Heavy live rollers or plastic modular belt conveyors are primarily used for conveying piles of boards usually conveyed horizontally. Special heavy-duty belts with appropriate characteristics allowing them to operate in tough conditions are required.

Technical Requirements

In addition to positioning the pile precisely, the belts must be able to convey the boards reliably and so that they don’t slip. As heavy forklift trucks convey the piles elsewhere, the conveyors and the associated belts need to be extra hard-wearing.

Our Solution

Forbo Movement Systems’ belts for this step in the process specialize in conveying heavy goods. Robust and exceptionally durable belts from the Siegling Transtex product range can for example drive heavy live rollers.

The Siegling Transtex belts keep to their dimensions, are flexible, quiet and can withstand moisture and chemicals. They’re easy to make endless, allow simple conveyor designs and stand apart for their low energy consumption. Siegling Prolink plastic modular belts from series 7, 8 or 9 enable various customized solutions. The Siegling Prolink series are very strong and durable belts with excellent tensile strength. While series 7 and 8 are ideal for straight sections, series 9 has been developed for curved sections.

You can find detailed information on suitable products in the relevant brochures, for example: Siegling Transtex Conveyor Belts, ref. no. 214 and Siegling Prolink Modular belts - Product Range, ref. no. 800.

From pre-inspections to factory acceptance inspections to staff training, the service we provide doesn’t start or finish when a belt’s purchased. Here are some examples:

An on-site inspection ensures that the project’s perfectly planned. And just two to three days for fitting are required and then production can be restarted. This allows you to minimize both downtime and costs.

You can also carry out factory acceptance inspection of the plasterboard setting belts before delivery. Consequently, you’ll be able to see our superior belt quality for yourself.

But it’s not just the belt we deliver - each one also comes with its own test certificate and a file with handling, cleaning, repair instructions etc. This gives you everything you need to ensure your belt’s reliable.

After fitting a new belt, our experts train the customer’s staff in handling, cleaning and maintaining it. This ensures belt quality is maintained from the word go.

We offer a repair set so that customers can put right minor surface damage on the belt, such as scratches or small holes, themselves. Therefore, minor damage can be removed within a short space of time.

We offer efficient tools so that customers can splice many belts in their own production facility. So you choose the time that suits you and your workflow.

And of course our global service network of experienced specialists is on hand to provide support. We offer personal advice and are happy to answer your questions because complex projects need clever solutions and we ensure that your plans stand on robust foundations.