Belts for Chocolate Production

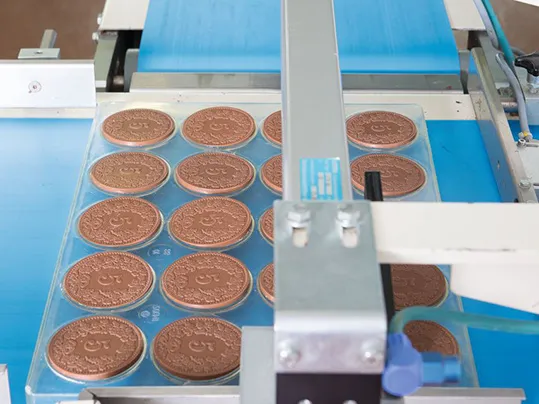

Chocolate making is an art. It’s a fascinating and complex process. People worldwide enjoy this delicious confectionery. And making it involves lots of individual steps.

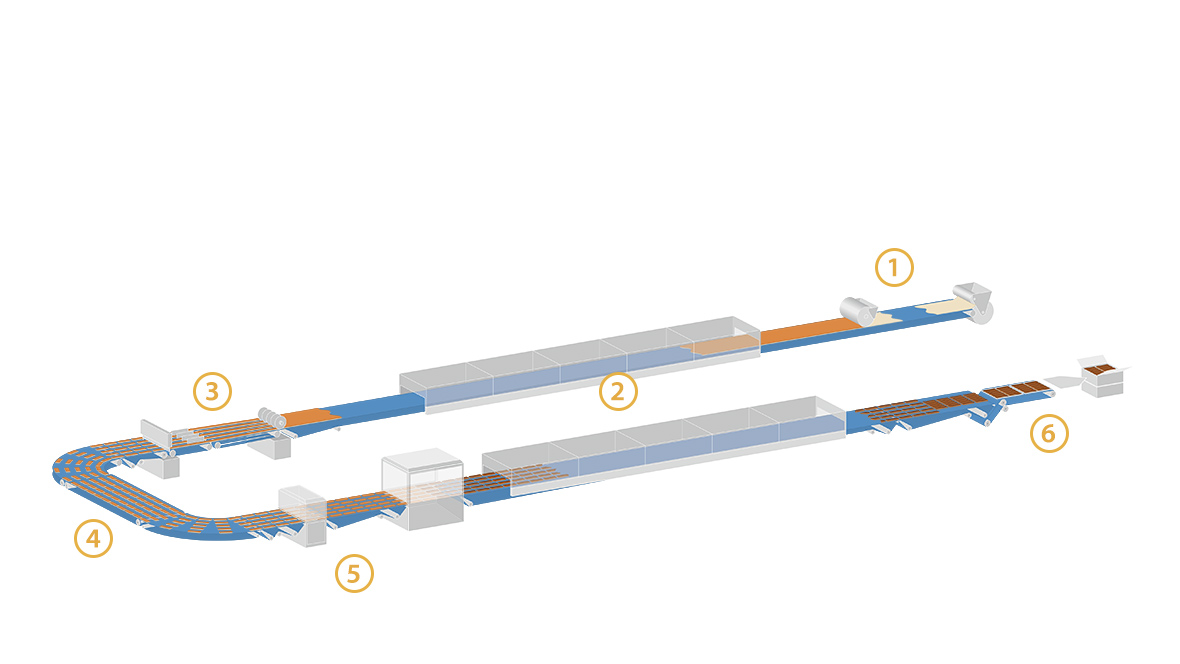

Without processing belts, there would be no chocolate. Because they have a major impact on the efficiency, precision, and quality of the finished product. Production involves forming, cooling, cutting, coating, and ultimately packaging the chocolate. To achieve a perfect result, each steps places specific demands on the conveyor belts concerned.

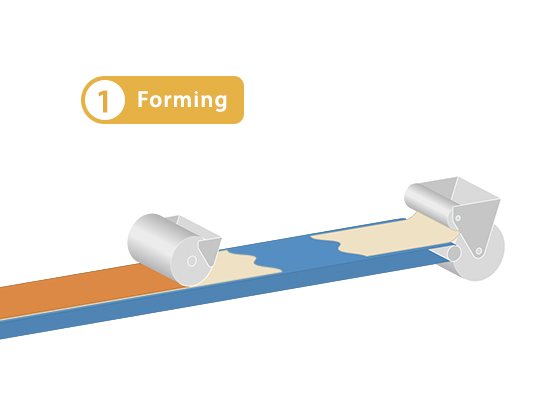

Do you make chocolate in bars, small portions, or with special ingredients such as nuts or fruit and cereals? The range of options on the production line is virtually endless. To achieve the desired shape, endless, wide strands of chocolate are first formed on the belt by extrusion or other types of molding (e.g. rolling).

These strands consist of fat, soft- and hard-boiled sugar masses, aerated fat- and sugar-masses, and various mixtures with a range of ingredients.

Technical Requirements of the Belts

Processing belts in chocolate production must be food safe and resistant to oil, lecithin, and grease. For perfect chocolate, the belts also need to have excellent release properties in order to minimize the use of release agents. Good grip, superior positioning accuracy and temperature resistance are imperative. During rolling processes, the belt needs to be able to withstand the pressure and kneading action from the rollers.

Our Solution

We offer a wide range of HACCP-compliant belts for forming processes. These belts meet stringent hygiene standards and the requirements stipulated by the EU and FDA. If hygiene requirements are particularly rigorous, our Smartseal belt edge sealing can be applied to lots of belt types.

To guarantee outstanding release and grip, we offer diverse coatings and patterns tailored to the process concerned.

These easy-to-clean materials are resistant to oil, lecithin, and fat. Above all, they’re temperature resistant.

Special tension members mean the belts retain their dimensions and don’t elongate during rolling.

Contact us if you’d like to know more

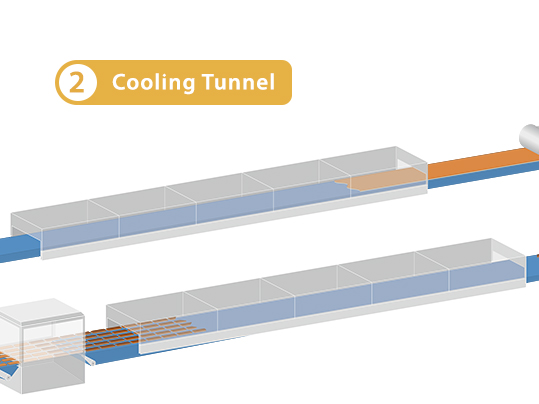

To obtain perfect texture, consistency, and a glossy finish, chocolate passes through a cooling tunnel. As a result, the chocolate cools down gradually and evenly to an ideal temperature for further processing. When it enters the cooling tunnel, the chocolate mass’s temperature can be up to 160°C. This depends on the temperature it was processed at. Depending on the process, various cooling options using air jets, refrigerants, convection, cold plates, or a combination, are used.

Technical Requirements of the Belts

The belts must be food grade, guarantee good grip and release properties and enable small end radii.

Despite relatively high temperature differences, the conveyor belts must retain their dimensions in the cooling tunnel. They also have to remain absolutely flat so that no dishing occurs. Just like the shape of a dish, the edges of unsuitable conveyor belts can bend or curl over.

The belt must not impair the cooling process.

Our Solution

We can offer a range of HACCP-certified belts for cooling tunnels. These belts comply with the most rigorous hygiene standards stipulated by the EU and FDA. They also stay flat, retain their size and are resistant to temperature. These easy-to-clean belts also have excellent release properties. Their suitability for knife edges enables product transfer over tiny gaps and therefore much more efficient production.

Belt elongation is prevented thanks to tension members with high K1% values. The special fabric design stops creasing on the belt edges.

A high K value encourages effective discharge of heat from the chocolate mass. Our customized, embossed belt surfaces allow a tailor-made design of the bottom of the products. We recommend our tried-and-true Smartseal belt edge sealing for very hygiene-critical products.

CONTACT US IF YOU’D LIKE TO KNOW MORE

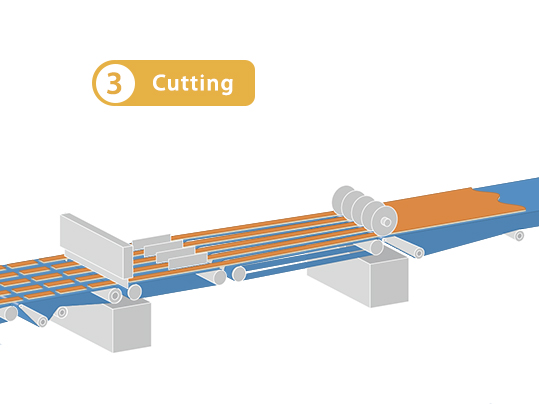

Once solidified, the chocolate mass is turned into its ultimate shape. The cutting process governs the size and shape of the chocolate products. During production, the solidified mass is first cut lengthwise and then crosswise.

Afterward, the pieces of chocolate are packaged, or covered with more ingredients such as spices, nuts, or dried fruit.

Technical Requirements of the Belts

Conveyor belts destined for chocolate production must be food safe, offer superior cut resistance and positioning accuracy. The edges cut must be very clean, both in products made purely of chocolate and those blended with other ingredients.

Our Solution

Our belts with their robust and incision-resistant polyurethane coatings are ideal for rotary cutters and cross cutters. These easy-to-clean options enable exact positioning and good product release. Thanks to its customized damping properties, the belt’s material encourages a clean cut through the confectionery. Its knife-edge suitability ensures easy product transfer with tiny gaps.

To guarantee outstanding sanitation and safety standards for exceptionally hygiene-critical products, belt edge sealing (Smartseal) can be applied to many of our belts.

CONTACT US IF YOU’D LIKE TO KNOW MORE

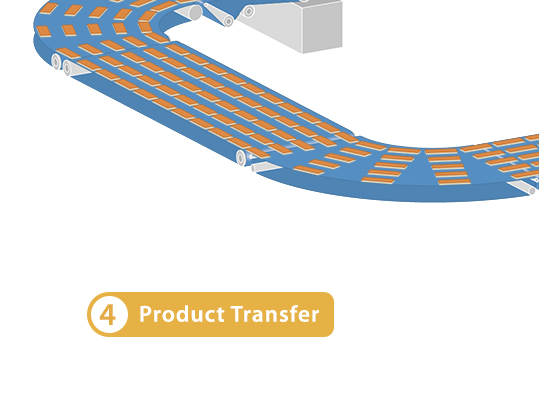

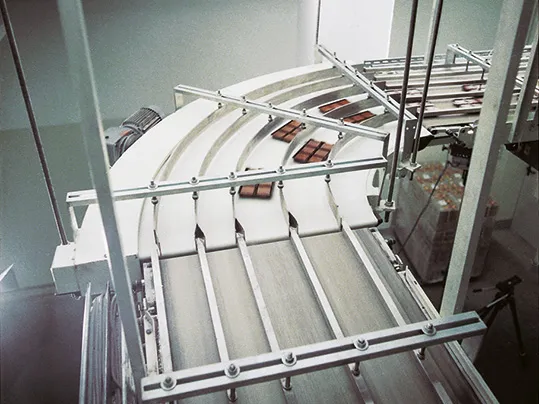

Is there plenty of space in your production facility to transfer products easily? This frequently isn’t the case in the real world. Between each of the processing stations, the material flow often shifts direction and changes in the conveying level occur.

Technical Requirements of the Belts

To convey products between each processing stage, the belts need to have exceptional positioning accuracy and be suitable for contact with food.

We recommend belts with a patterned surface if products need to be conveyed at a particular angle.

As there are lots of transfer points, very small end radii, or knife edges are required. Furthermore, curved belts must be suitable for belt guidance systems and their shapes especially accurate.

Our Solution

Our HACCP-certified belts offer top standards of hygiene. To offer superior grip and release properties, they also come in various coating materials and patterns. These easy-to-clean belts comply with the EU and FDA standards too. With enhanced fabric and belt designs, they’re the top choice for knife edges, or as curved belts.

To guarantee even higher standards of sanitation for exceptionally hygiene-critical products, belt edge sealing (Smartseal belt edge sealing) can be applied to many of our belts.

CONTACT US IF YOU’D LIKE TO KNOW MORE

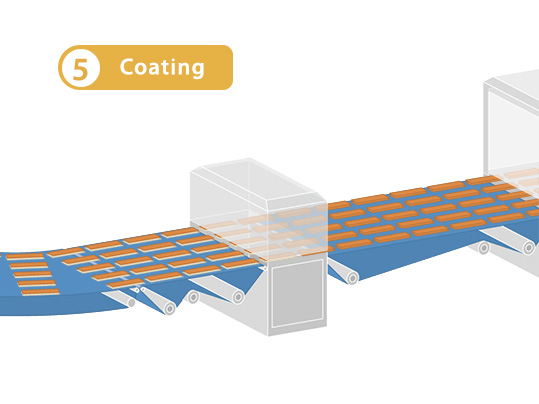

Once the mass has been cut, it can be coated once or several times with a thin layer of melted chocolate for instance. As a result, the products are given a smooth and tasty coat, or extra taste or texture. The products normally run through a sheet of melted coating. Afterward, they might be sprinkled with other ingredients or coated again.

Technical Requirements of the Belts

To ensure consistent quality of the coated chocolate products, the conveyor belts need to enable stable and even product flow.

To handle the flow of hot chocolate, the belts must have an extremely large open area and withstand high temperatures.

Our Solution

Metal mesh belts are normally used when the cut chocolate is coated. Our broad portfolio of conveyor and processing belts does not yet include these special types.

CONTACT US IF YOU’D LIKE TO KNOW MORE

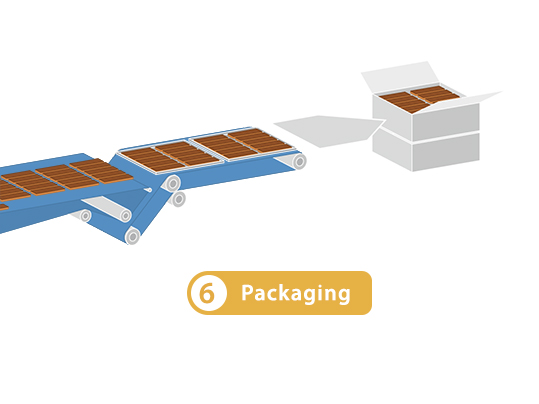

Your chocolate products are now ready and just require packaging. Packaging chocolate involves lots of steps. The goal is to preserve the quality and flavor of the chocolate while meeting aesthetic, practical, and hygiene requirements. The chocolate is separated, covered in foil, packaged into boxes, and finally transferred to pallets. Each step in this process requires special methods and a conveyor belt to match.

Technical Requirements of the Belts

The technical requirements of the belt are just as different as all the packaging processes. The belts need to reflect the type of processing and conveying, or the parameters required by the machinery concerned. These characteristics include, for instance, superior elasticity, light permeability, or exceptional tensile strength.

Our Solution

We can offer you a comprehensive portfolio for any packaging machinery. As a result, you’ll be able to exploit your chocolate production line’s quality- and productivity-potentials to the full. For sub-processes we can supply fabric-based belts (Siegling Transtex, Siegling Transilon, Siegling Extremultus) and plastic modular belts (Siegling Prolink), timing belts (Siegling Proposition), and round belts (Siegling Transilon).

Due to their consistent thickness and particularly precise endless splices, our check-weigher belts make endless belts superfluous.

As buffer belts, elastic ones with easy-to-clean surfaces help you get the most out of your packaging machinery. Light-permeable belts mean that image-based robots (Pick&Place) can be used. And temperature-resistant belts enable the use of shrink tunnels. Our FDA- and EU-compliant folder gluer belts are ideal for folder gluers.

CONTACT US IF YOU’D LIKE TO KNOW MORE

In the fascinating world of chocolate production, conveyor belts play a vital role. They ensure perfect chocolate production to a high quality.

For your chocolate process, our special belts with innovative belt edge sealing (Smartseal) offer exceptional hygiene and guarantee high-quality chocolate that’s fit for human consumption.

In terms of adaptability and precision, our HACCP-certified belts are top choices. They come in a wide range of coating materials and patterns, tailored to the demands of your chocolate production line. These very easy-to-clean belts meet stringent EU- and FDA-standards with ease. What’s more, they guarantee that each chocolate product is superb and meets high standards of quality.

Looking for the right conveyor belts to make your chocolate production efficient? We’d be happy to help you and find the belts that match your requirements.

Any questions about our products for chocolate production? Then contact us.

To the contact form