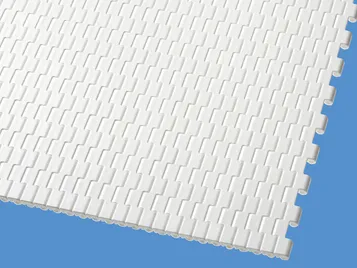

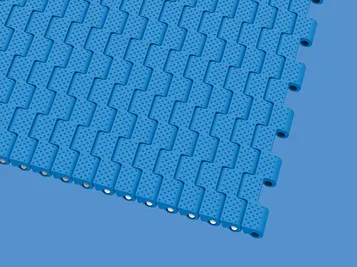

Design characteristics

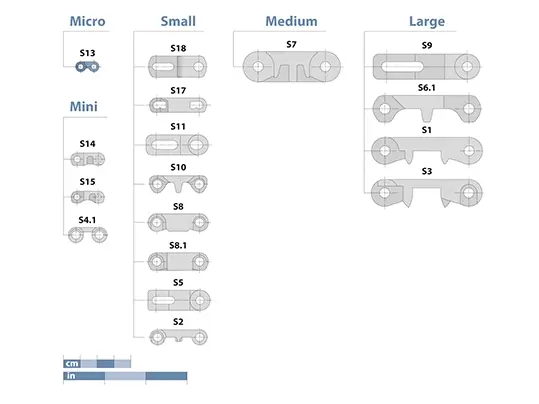

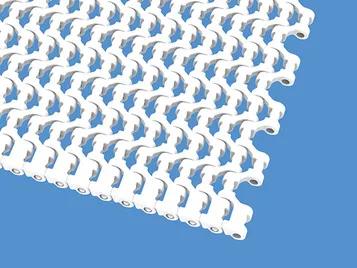

- Micro pitch belt with small transfer gaps

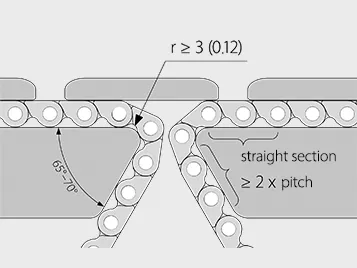

- Designed to run over nosebars/knife edges or rollers with a radius down to 3 mm (0.12 in) allowing, precise transfer of even the smallest products

- Versatile for conveying, drying and cooling applications

- Optimal design of sprocket teeth, and belt underside pro-

vides superior sprocket engagement, safe belt tracking and favorable cleanability - Belt and sprocket design ensures superior load transmission and belt pull capacity

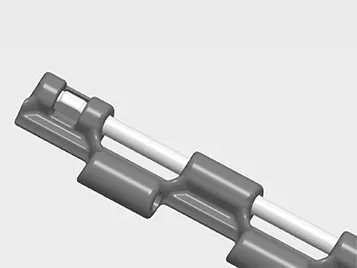

- Headless pin making it very easy to install and remove the belt for maintenance