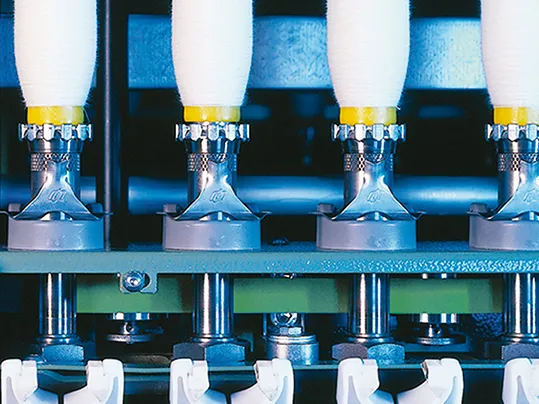

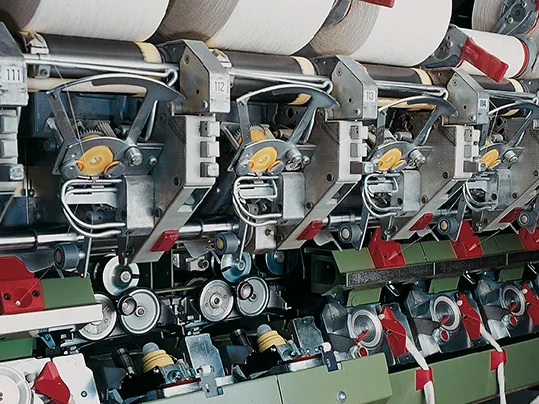

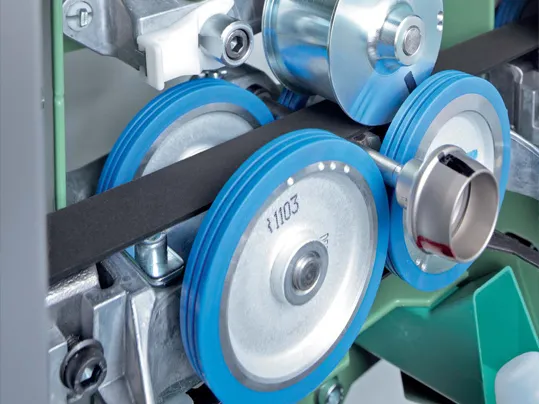

Sectional tangential belt drives

These types of drive place high demands an the tangential belt:

- the ability to withstand high mechanical and thermal stress on the belt surfaces – especially during spindle stop and acceleration

- precise belt tracking with little oscillation

- greatest possible belt flexibility as well as a simple, reliable endless splice

The properties of the Siegling Extremultus A + E line are used to their fullest advantage on this application. The highly-modular, flexible belt design saves energy and minimizes RPM variations in the section of spindles. The precise Z-splice ensures that the belt tracks with little oscillation, treating the machinery gently. Yarn quality and service lives of the drive components increase, energy and maintenance costs drop.