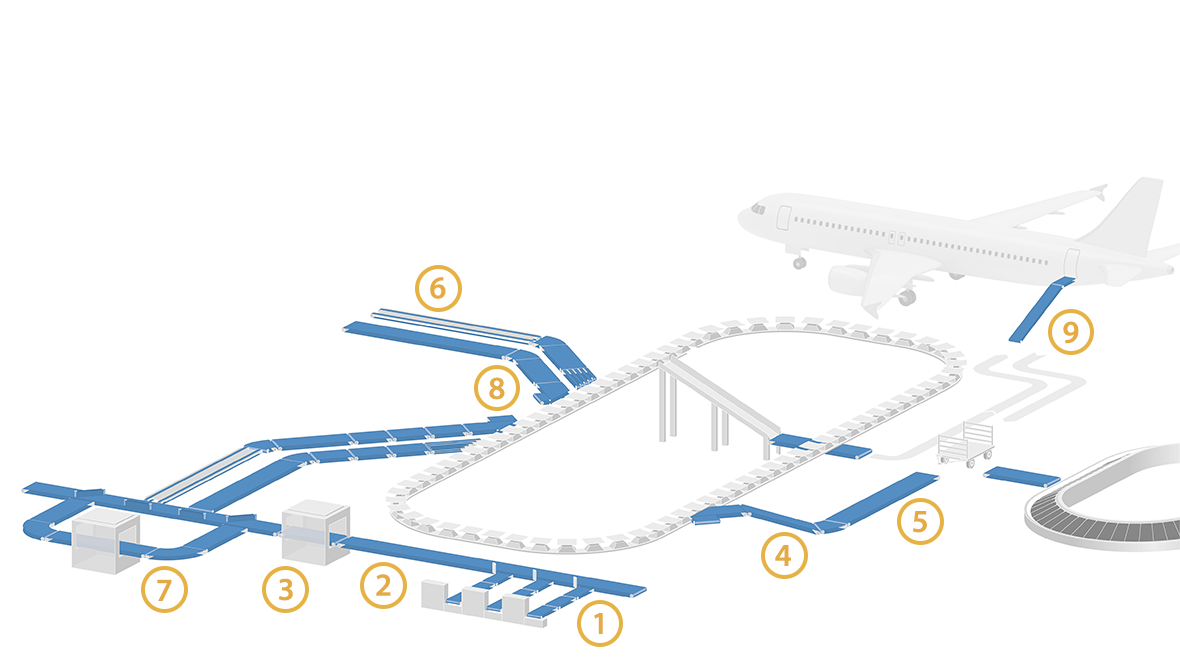

Baggage handling process

Before departure, passengers check in baggage and expect it to arrive at the destination on time. Passengers are unaware of their cases’ journey from the check-in to the aircraft and on to baggage claim. But it’s a well-oiled logistical operation. In the process, baggage safety, perfect handling and speed enjoy top priority. To ensure travelers’ baggage is waiting for them in one piece at the destination, these aspects are vital.

Conveyor and processing belts are key to successful baggage handling logistics. We’ll show you which belts are best suited for each step in the process.

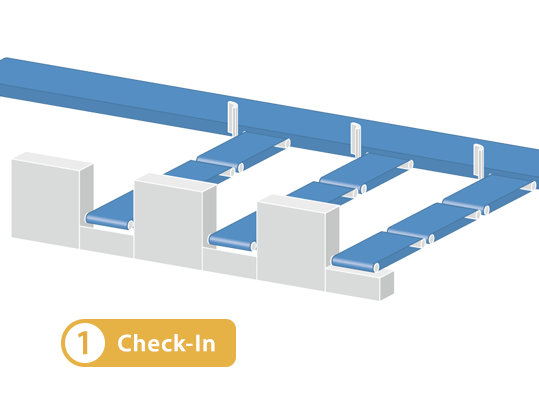

Baggage is conveyed to aircraft from check-in facilities. It’s weighed and tagged or coded there. Coding allows the baggage handling system to identify the baggage’s location and ensures that it’s sent to the right aircraft.

Technical Requirements of the belts

Our belts ensure that items of baggage are conveyed to the next stage in the baggage handling system. They prevent baggage from rolling back when a conveyor starts or stops or when inclined check-in conveyors are used. The belts need to have robust surface patterns and fabric designs to handle the vast quantity of baggage placed on them at exceptional point loads, as is the case with trolley suitcases.

Our solution

Forbo Movement Systems offers robust, double-ply polyester types with a rhomboid pattern or custom-developed check-in patterns. In terms of size and thickness, both are designed to guarantee trolley suitcases are grabbed properly.

Contact us if you’d like to know more

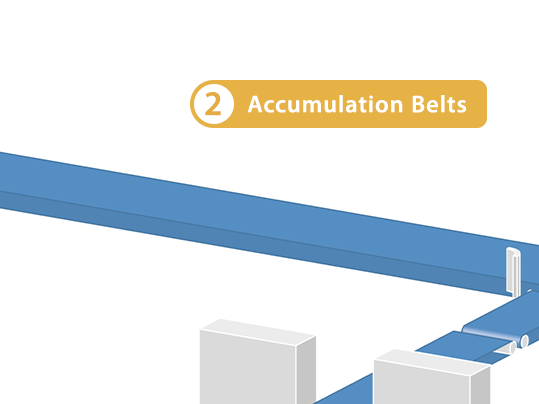

Accumulation belts take all items of baggage from check-ins and feed suitcases to the actual baggage handling system.

Technical Requirements of the belts

The belts have a smooth and hard surface and are very laterally stiff. As a result, suitcases are easy to push onto these belts from the sides. These belts are usually very long, often as long as the whole check-in station.

Our Solution

Forbo Movement Systems has diverse belts in its portfolio that are perfect for accumulation. They have the lateral stiffness and excellent grip required. Amp Miser belts are exceptionally energy efficient, as the long route they take promises huge potential for saving energy.

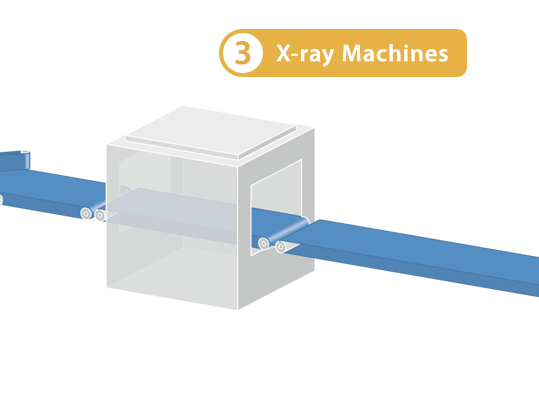

Security has top priority at airports. Which is why all items of baggage are checked by x-ray equipment to ensure they contain nothing that could jeopardize flight safety. For some years now, this has applied to carry-on items and items of baggage checked in as well.

Technical Requirements of the belts

It’s imperative that conveyor belts don’t cast any shadows during baggage screening. To prevent anything being out of focus on the x-ray image, the belts must be absolutely flat and track in a straight line through the x-ray equipment at the same speed.

Our solution

Regardless of the way the equipment’s used, tension members, coating materials (PVC or urethane) and surface patterns (e.g. quartz sand pattern) can be selected from a large portfolio. We have belt types with excellent screening characteristics for any kind of x-ray equipment. These belts can be spliced without any additional materials, such as films. The homogenous splices practically rule out the possible of shadows or dark areas on the images. The belts meet all the precise tracking demands required for x-ray equipment.

Contact us if you’d like to know more

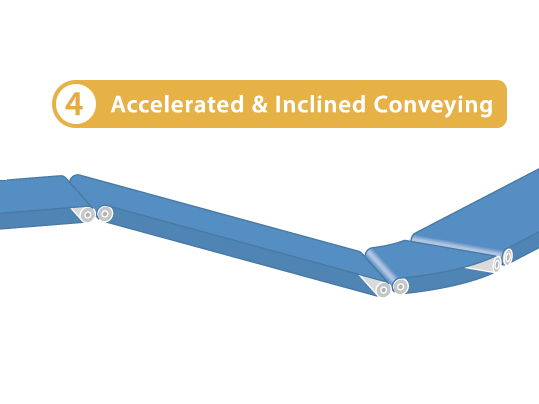

During acceleration and inclined conveying, it’s imperative that items of baggage remain in place. If exact tracking of their position at any time proves impossible, huge disruptions to the process will occur.

Technical Requirements of the belts

Surface materials and patterns must be designed so that items of baggage can almost consistently keep to their original position on the belt. The belts are also expected to operate continuously for long periods of time.

Our solution

Our portfolio offers various belts that are robust and have excellent grip. Regardless of the application concerned, PVC and PU coatings can be used with various degrees of Shore hardness or also come in high grip materials (R coatings). Longitudinal grooves (LG) and inverted pyramid (NP) are patterns with good track records.

Contact us if you’d like to know more

Items of baggage are often conveyed horizontally over long distances, from the check-in to the sorter and from there onto the aircraft. To cover these distances, a high proportion of the total energy consumption is required by the conveyor.

Technical Requirements of the belts

Which is why energy-efficient belts on horizontal conveyors produce a very quick ROI. These belts also need to be robust and low noise. Flame-retardant, EN 340-compliant belts are also normally a must.

Our solution

Transilon Amp Miser belts reduce the friction coefficient and therefore energy consumption drastically. Savings of up to 50% are possible. From a broad portfolio of robust types, Forbo Movement Systems can supply fabric-based or polyester-felt belts. Our low-noise belts with a special fabric pattern operate very quietly.

Contact us if you’d like to know more

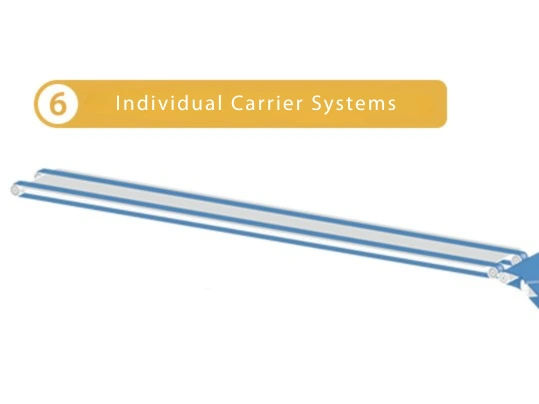

Items of baggage are conveyed in trays, particularly in high-speed sections. These keep the baggage safe, decrease damage and enable much better tracking in the baggage handling system. The trays are positioned on the outside on two narrow, parallel conveyor belts or on timing belts. These baggage-tray systems achieve speeds of up to 12 m/s.

Technical Requirements of the belts

The fast conveying speeds require durable undersides that operate smoothly. At the same time, the coating materials and patterns on the top face have to ensure conveying of empty and heavy baggage tubs without them slipping. Due to relatively long conveyors and heavy loads, the narrow conveyor belts are subjected to a lot of tensile stress.

Our Solution

Twin- or triple-ply belts with fabric undersides offer a combination of exceptional tensile strength and smooth operation. Coating materials with a high friction coefficient and longitudinal grooves (LG patterns) deliver the required grip. Belts with high-grip coatings (R coatings) have excelled where exceptionally good grip is required.

An OEM solution with three types of timing belts is also applied. The timing belts stand apart because of their exceptional strength and smooth operation. They enable fast acceleration and exact positioning of the tray. The belts are durable and very resistant to wear, therefore guaranteeing efficiency.

.webp)

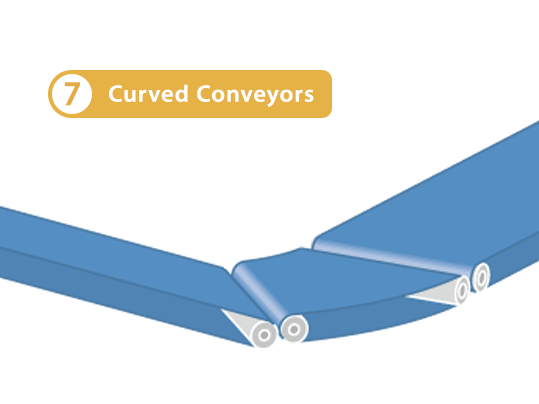

Curved conveyors change the direction in which items are moved on the conveyor itself. Standard curve angles are 30°, 45°, 60°, 90°, 135° and 180°, but any angles in between are possible, depending on the conveyor’s layout. They normally have tapered return drums, but some curve manufacturers also use cylindrical drums.

Technical Requirements of the belts

The key criterion for curved belts is an even distribution of force in the fabric in all directions (lengthways, crossways and diagonally) to ensure the belt tracks without any creases and bulges.

Our Solution

Thanks to a special tension member fabric, our curved belts guarantee outstanding distribution of force within the belt. Belts with C-fabric offer ideal force ratios of 1:1:1 lengthways, crossways and diagonally. Suitable surface patterns are available even for very fast belt speeds. All belts are cut to size on a CNC cutter and perfectly geared to the shapes of the different conveyors.

Contact us if you’d like to know more

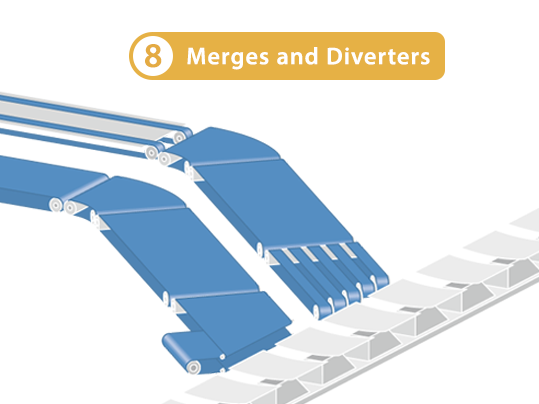

The sorter is the nucleus of the baggage handling system. All items of baggage checked in are merged in here and (depending on their destination) also diverted again at defined points. Merging often occurs at a 30° or 45° angle to the direction the sorter is conveying in. These conveyors either have one single wide conveyor belt (a full-belt merge), or several narrow belts that run parallel as a set (strip merges).

Technical Requirements of the belts

Both designs require the belts to have high surface friction to enable precise and slip-free transition of baggage to the sorter. In full belt merges, the belt runs over various deflection rollers and even over a knife edge. The coating materials must be able to absorb the temperatures caused by friction and flexing without becoming damaged.

In the case of strip merges, all belts operating in parallel in a set are stretched with just one tensioning roller. In order to achieve standard tension, compliance with tight length tolerances is a must.

All merge belts must meet the same technical requirements as curved belts.

Our solution

Forbo Movement Systems supplies belts with a low-friction fabric underside and a top face with the grip needed for both conveyor types. Belts with special, very flexible curved belt fabric and polyurethane as the coating material are predestined for use on full-belt conveyors.

Belts that run in parallel as a set are custom made for strip merges. We place top priority on precise manufacturing and compliance with the tightest length tolerances and, if required, the position of tracking profiles.

Contact us if you’d like to know more

Aircraft are usually loaded and unloaded by outdoor inclined conveyors. The belts move all sorts of baggage and are constantly exposed to typical local weather conditions, which can fluctuate hugely.

Technical Requirements of the belts

The impact of rain, snow, hail and ultraviolet rays requires the fabrics and coating materials to be weatherproof. A robust, puncture-proof belt has to be able to absorb the high levels of mechanical stress when items of baggage are thrown onto it. Inclined conveying requires sufficiently high friction coefficients to ensure reliable grip.

Our Solution

Belts with robust fabrics and weatherproof coating materials ensure conveying is reliable and doesn’t disrupt operations. The most suitable ones are Transtex types from the PHR line that often have rough top (AR) or nonslip coatings.

Contact us if you’d like to know more

Our experts can tell you anything you want to know about conveyor belts at airports.

To the contact form