Hanover, March 6, 2023 – Sustainable products and extensive customer services in Hanover, Germany, on stand 9040, in hall 21

Conveyor and processing belts with tension members made of recycled PET: Transilon ECOFIBER

Compared with the primary material and in an identical quality, yarns made of recycled polyethylene terephthalate (rPET) save valuable raw materials and help reduce the production of more plastic. First-class tension member fabric for fabric-based conveyor belts is made from these yarns. R-PET or rPET stands for recycled PET.

The recycled material for the ECOFIBER yarns made of rPET is obtained from post-consumer drinks bottles. These drinks bottles have already been used and are then are shredded following careful separation and washing. The resulting flakes are cleaned again, then melted down and processed into pellets, which act as raw material for various types of yarn. Forbo Movement Systems only uses fabric whose yarns are made of rPET for the new ECOFIBER conveyor belts.

Combined with our patented AMPMISER on the underside, extra energy savings are possible during operation, which also helps reduce carbon emissions.

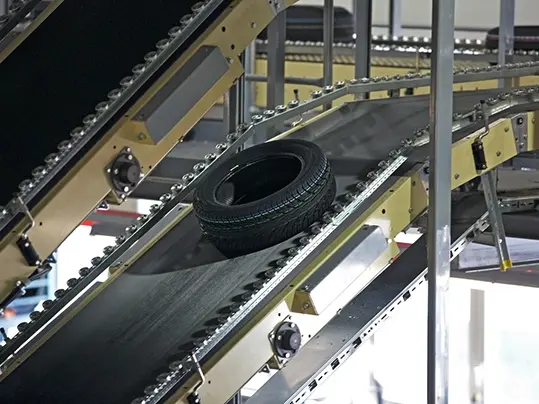

Always One Step Ahead – Forbo Movement Systems Showcases Conveyor Belt Solutions and Expertise for the Tire Industry at the Tire Technology Expo 2023

Belt monitoring

To users who are interested, Forbo is showcasing a custom-developed, beta version of an app that identifies Forbo belts clearly when they’re fitted thanks to a laser-printed QR code on the belt. From fitting to removing the belts, this app helps to document and handle all the core processes online.

Without the need to conduct time-consuming searches, all the relevant information about the belt is available or can be stored if required. Service requests, quote requests or even repeat orders are therefore possible at the touch of a button.

Forbo makes conveyor- and plastic-modular-belts, which are key to guaranteeing flawless material flow and economical production processes, from mixing raw materials to storing finished tires in difficult environments. And it offers an extensive range of services too. Customized service packages and 300 service points around the world ensure rapid availability of spare parts and services around the clock.