TRANSILON ECOFIBER

More sustainability in terms of conveying, shipping, and processing.

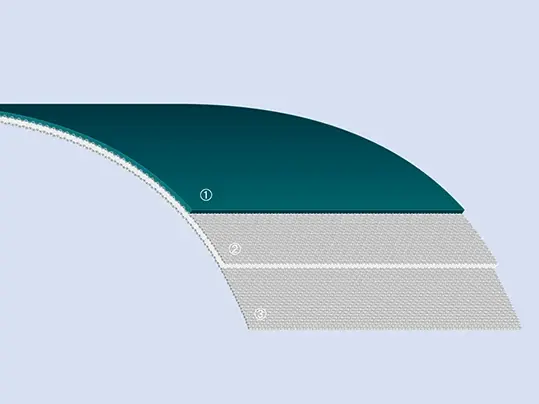

Aiming for sustainable processes is integral to our global corporate strategy. Which is why we’re making a concerted effort to increase our resource efficiency and our products’ environmental footprint. We also supply innovative products to improve our customers’ own energy footprint and sustainability. How are we doing this? With conveyor and processing belts that save primary raw materials thanks to a tension member made of recycled PET.

The United Nations’ 2030 Agenda has established 17 sustainable development goals for a better future. This agenda’s objective is to improve people’s lives worldwide and protect the planet sustainably. As a company that’s aware of its social responsibility, we identify with these goals and respond wherever we can make the biggest impact. We’ve been taking steps to protect the environment for a long time now and consistently invest in a sustainable future. We can help you reach your sustainability goals too: Conveyor and processing belts with tension members made of recycled PET.

At the same level of quality as the primary material, yarns made of recycled polyester (rPET) save valuable raw materials. At the same time, the energy consumed to make them, and therefore carbon emissions, is much lower. First-class tension member fabric for fabric-based conveyor belts are made from these yarns.

Learn more about the benefits of Transilon ECOFIBER: The conveyor belt for sustainable conveying

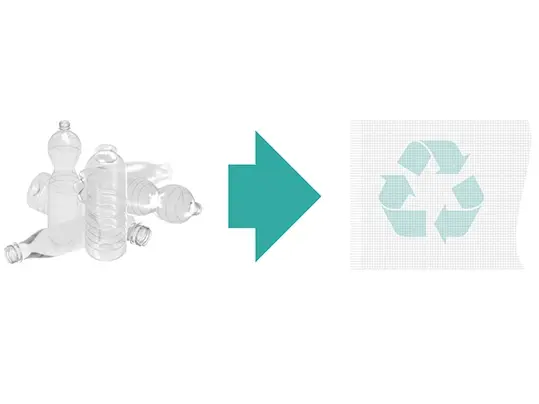

R-PET or rPET stands for recycled PET. This is the more sustainable version of PET (polyethylene terephthalate), a type of plastic that’s chiefly used for drinks bottles and most of the tension member fabrics in our tried-and-true Transilon belts. We now only use fabric made of rPET yarns for the new ECOFIBER conveyor belts.

The recycled material for our ECOFIBER yarns made from rPET is obtained from post-consumer drinks bottles. These are drinks bottles that have already been used, which are first sorted according to color, then thoroughly cleaned, and shredded after labels and caps have been removed. The resulting flakes are cleaned again, then melted and processed into pellets, which act as raw material for various types of yarn. Finally, the rPET yarn is woven into fabrics, which are then used as tension members for our conveyor belts – just like fabrics made from primary PET.

As part of its sustainability strategy, Forbo Movement Systems is consistently forging ahead with the development of sustainable products and services. As a result, we can offer our customers products that are made from sustainable, recycled materials and have features that verifiably enhance customers’ sustainability performance.

Our customers can choose from the Transilon ECOFIBER portfolio according to their own sustainability preferences:

Sustainability feature: belts with fabric made from recycled PET

>Benefits: Saving valuable raw materials, avoiding waste

Sustainability feature: Belts with fabric made from recycled PET and PVC made from bio-based oils from the food industry

>Benefits: Saving valuable raw materials, avoiding waste, supporting genuine recycling.

Sustainability feature: Belts with fabric made from recycled PET and special underside finish

>Benefits: Saving valuable raw materials, avoiding waste, saving electricity/costs, lower CO2 emission.

Using yarns made of recycled PET saves several tonnes of carbon dioxide annually. If we take just 30 of our Transilon belts, the potential annual savings are approx. 1,400 tonnes of carbon dioxide if only recycled PET yarns are used.

Dr. Torsten Buch, vice president of the Transilon/Transtex product line, managing director of Forbo Siegling GmbH, comments on the quality of Transilon ECOFIBER:

“All our lab and field tests show that yarns made of secondary raw materials perform just as well as the yarns previously used. Conveyor and processing belts with tension members made of recycled PET are identical to the quality of belts with tension members made of new PET. They’re equally stable and their breaking and tensile strength, as well as thermal stability, make them ideal for producing tension members.

We’ve been applying conventional PET to make belts for decades. By using recycled PET, both we and our customers (who operate these belts) are saving valuable resources. And the clever part is that the quality’s the same. Recycled PET takes us a step further to a circular economy.”

We’re sure you’re interested in getting your company in shape for the challenges of a society and environment that have changed. And that you want to develop a strategy for the future that’s sustainable and supported by your own customers too. We’d like to offer you the opportunity to talk to our experts about the future. Let’s develop specific areas to tackle together. Contact us to discuss your ideas for making your business more sustainable.