Processing belts for every step

All types of dough are unique. Each mixture and consistency places exceptional demands on the whole process, particularly the conveyor belts.

Conveyor belts play a key role in dough processing and really help to make the whole production process smoother and more efficient. It takes hygienic conveyor belts in bakeries, patisseries, and other food-processing sectors to automate processes and increase productivity.

But how do you find the right belt for your applications, process steps and other any other needs?

“Once we know your requirements, we can help you pick the belt that’s right for you. Because each type of dough has different characteristics. And these are important for conveying the dough on the production line. We’re happy to help find the belt for your processes.”

In all areas of the food industry, Siegling Transilon belts are real all-rounders for special conveying and processing tasks.

To the Siegling Transilon Belts product finder

Exceptionally resistant to oil, grease, moisture and bacteria, our homogenous conveyor belts are ideal for all unpackaged food processes.

Siegling Fullsan – the powerful, more hygienic solution

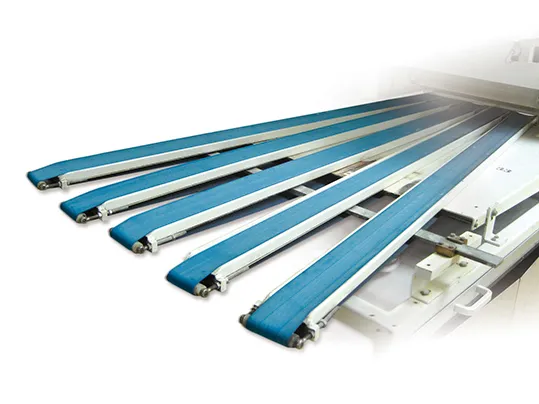

Siegling Prolink plastic modular belts allow you to tailor conveying and processing operations to your needs. The materials used, the designs, spacing, surface patterns and levels of permeability make our modular belts the go-to options for your food production processes.

To the Siegling Prolink conveyor belt product finder

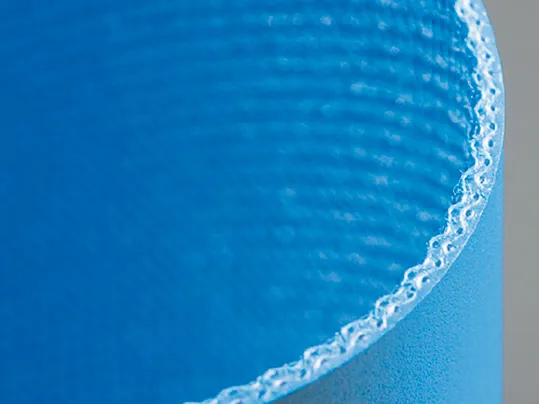

It’s vital to prevent lint forming on conveyor belt edges. We do so via a special fabric, a unique bond and optimized fiber lengths so that there's no fraying – even on unsealed belts.

As a result, our Frayfree belt types guarantee safety, so crucial in the food industry, and meet all hygiene standards.

Click here for more information about our Frayfree belts

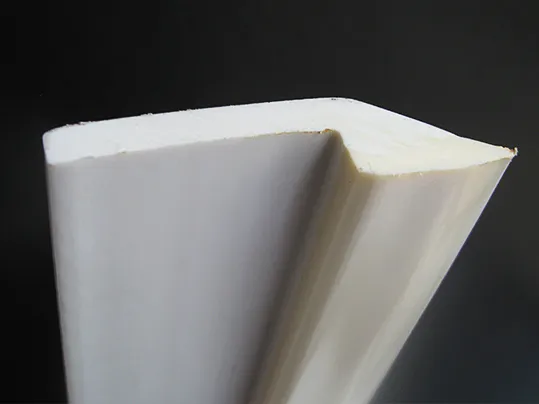

Do you need superior hygiene in plastic conveyor belts with fabric tension members? Firstly, our Smartseal belt edge sealing prevents oil, grease, water, and bacteria from penetrating the fabric. Secondly, this sealing method prevents lint from forming on the belt edges.

Information about our belt edge sealing

Are you looking for a gentle, but effective cleaning method for dough-processing conveyor belts? Our urethane belt scrapers allow you to clean belt surfaces and splices thoroughly while treating the surfaces carefully at the same time. These durable scrapers come in various colors and in a version with metal-detection capabilities (MD).

White belt scrapers

Beige belt scrapers

Blue belt scrapers

Blue belt scrapers with metal-detection capabilities

Special hygienic markings on conveyor belts improves process efficiency in a targeted way. These are used in areas requiring exact positioning. Laser printing allows you to add any shapes and symbols to the conveyor belts.

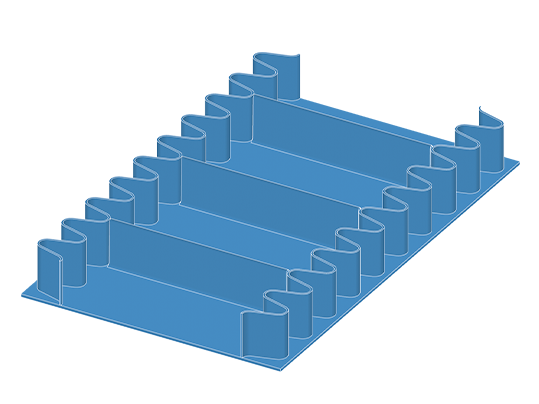

In the food industry, bulk materials, such as confectionery, flour or sugar, need to be conveyed very hygienically and without any product loss. We do so by providing side walls, which are easy to clean and can withstand oil and grease.

Information about the side wall range

Our cutting belts’ unique design are guaranteed to withstand processes involved with cutting out dough. These HACCP belts’ durability makes them a high-quality and economically attractive solution.

Click here for more information about cutting belts

Our homogenous, elastic belts made of urethane are ideal for check-weighers, labeling equipment, packaging machinery on spreader conveyors, or as acceleration belts and machine tapes. They stand apart for their very good release properties, troughability and dimensional stability. They can also withstand animal fats, detergents, and UV-C light.

Click here for more information about our elastic belts

Each type of dough behaves differently on conveyor belts. It sticks, is greasy or sugary. Therefore, the processing belts need appropriate release properties to ensure products come off the belts.

Depending on the top face’s physical properties and patterns, as well as the type of product conveyed (greasy or watery), we can offer a conveyor belt with ideal release properties for any product. For Instance, coatings with low surface tension are naturally nonstick and ideal for conveying sticky, sugary products.

Any questions about our dough-processing products? Then contact us.

To the contact form