Hanover, March 8, 2023 – Transilon ECOFIBER for more sustainability in conveying and transport

Forbo Movement Systems continuously promotes the development of sustainable products and services as part of its sustainability strategy. These innovative products, in turn, help users to improve their own energy balance and sustainability performance. Forbo Movement Systems has now achieved this by developing a transport and process beltthat saves primary raw materials by using an S fabric tension membermade of PET recyclate.

Saving CO₂ while maintaining quality – Sustainable belt construction with fabric made from recycled plastic bottles from Forbo Movement Systems

Conveyor and process belts with tension members made of recycled PET: Transilon ECOFIBER

Yarns made of recycled polyethylene terephthalate (rPET) save valuable raw materials with identical quality compared to the primary material. At the same time, the energy consumption and thus the CO₂ emissions during production are significantly lower. These yarns are used to produce first-class tension member fabrics for fabric-based conveyor belts. The term rPET or R-PET stands for recycled PET. This is the more sustainable variant of PET (polyethylene terephthalate), the plastic that is mainly used for beverage bottles and is also used for most of the tension carrier fabrics of the proven Transilon belts. For the new ECOFIBER conveyor belts, the belt manufacturer only uses fabrics whose yarns are made of rPET.

The recyclate for ECOFIBER yarns made of rPET is obtained from so-called post-consumer beverage bottles. These are already used beverage bottles, which are first separated by color, then thoroughly cleaned and finally shredded after removal of labels and closures. The flakes obtained in this way are cleaned again, then melted and processed into pellets, which serve as raw materials for various types of yarn. Finally, the resulting rPET yarn is woven into fabrics, which are then used as tension members for the Transilon ECOFIBER conveyor belts.

Significantly reduced energy costs and reduced CO₂ emissions by combining two belt developments from Forbo

Energy-saving Amp Miser™ belts have proven themselves for years in the tough everyday practice of logistics centers and baggage handling systems. The new generation Amp Miser™ 2.0 with optimized tension member achieves even lower coefficients of friction between the underside of the belt and the table – even with galvanized sliding tables. As a result, Amp Miser™ 2.0 conveyor belts can save up to 50% of the conveyor's energy consumption caused by belt friction . Forbo combines the advantages of Amp MiserTM 2.0 with the new ECOFIBER transport and processing system. At the same time, they ensure reduced power consumption, significantly reduced energy costs and reduced CO₂ emissions.

The right step towards sustainability

Two new Transilon ECOFIBER belts have now been successfully tested on the market and meet all technical requirements. They are superior additions to our range of belts for the logistics segment. What’s more, they now offer customers the opportunity to make another contribution to sustainability.

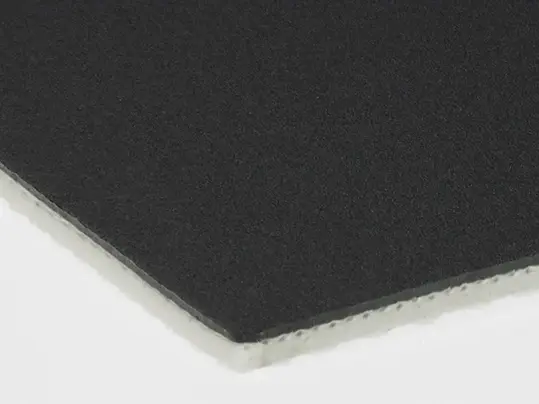

RE 10/2 TX0/V5H MT-SE-AMP black is flame retardant and can be used at airports and in parcel distribution centres for horizontal conveying of general cargo and baggage, as a stowage and deflector belt, for lateral pushing, as an assembly belt and for use on telescopic conveyors. RE 10/2 TX0/V15 LG-SE-AMP black with its longitudinal grooves surface structure on the base side is characterized by optimal entrainment properties. This belt can therefore be used at airports and in parcel distribution centers for the inclined transport of general cargo and luggage, as well as an acceleration and braking belt.

Future Dialogue

By using yarns made from recycled PET, many tons of CO₂ can be saved annually. For example, if only 30 of the Transilon belt types are considered, the potential savings per year are approximately 1,400 tonnes of CO₂ if only yarns made from recycled PET are used.

Forbo Movement Systems offers a future dialogue with experts in order to develop concepts for which products can be replaced by Transilon ECOFIBER.