Flat belts that hold on tight

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

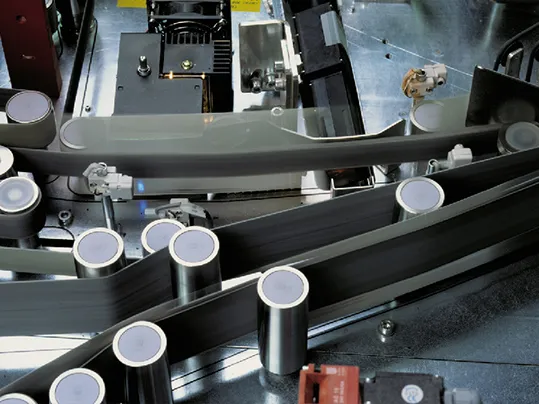

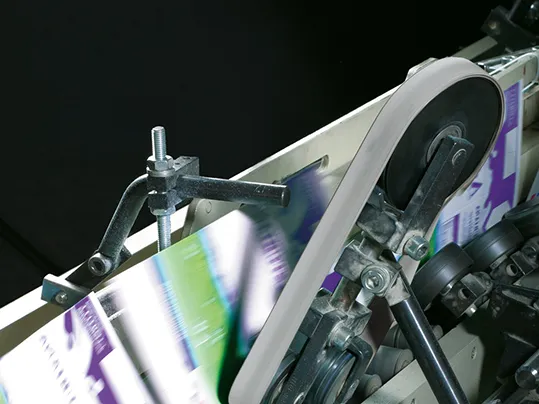

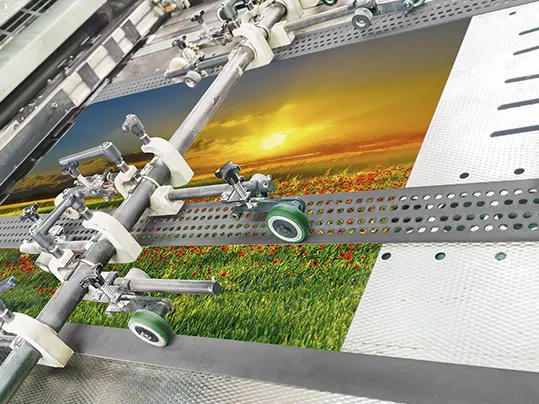

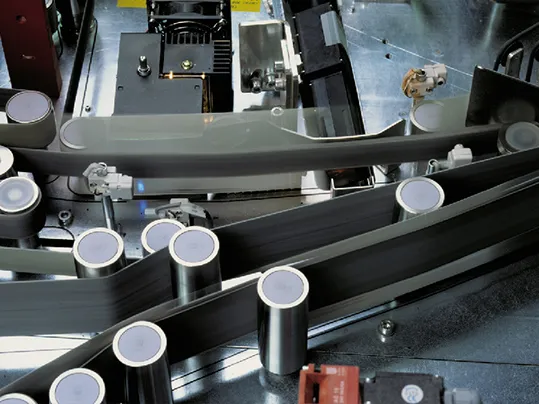

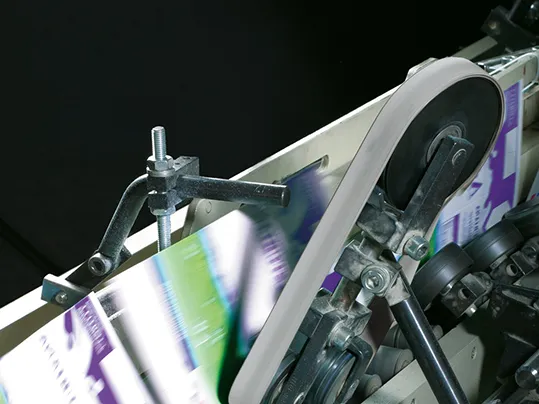

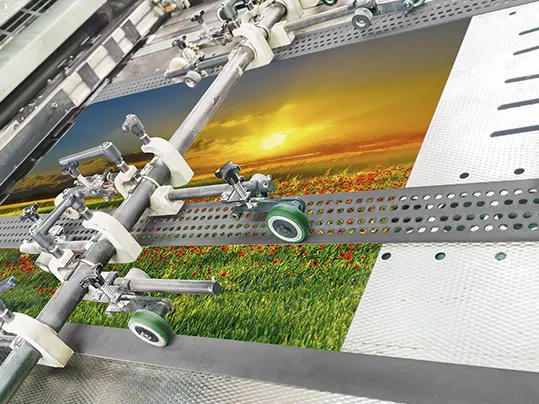

Grip Star flat belts are gentle with products, but still convey reliably. They take hold of and release products at precisely the right times. Grip Star flat belts can process paper, boxes, corrugated cardboard and tissue-based products dependably and efficiently.

Grip Star leaves no marks and has all the benefits of rubber. However, it doesn’t include the typical disadvantages of rubber such as brittleness and cross-cracking. Due to its excellent characteristics and good value, Grip Star is the better alternative to rubber. This is particularly the case when good grip, precise positioning, high levels of acceleration and high-performance braking are required.

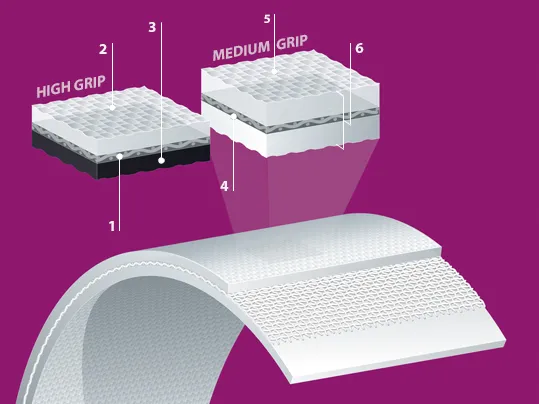

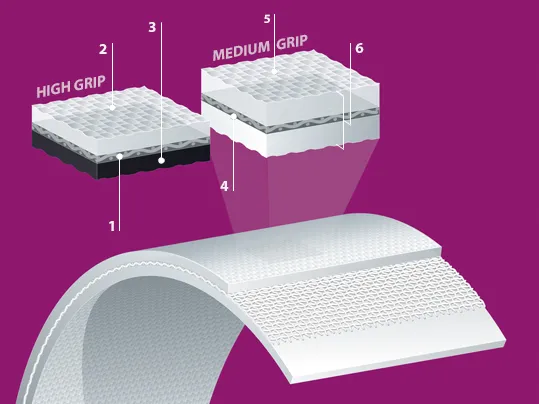

Grip Star is produced in High Grip or Medium Grip versions in different thickness and with specific surface patterns. As folder gluer belts, drag belts, live roller belts and machine tapes, the range’s belts fulfill exacting demands and offer a wide range of uses. The majority of the Grip Star belts comply with the (EC) regulations 1935/2004, (EU) 10/2011, as well as the FDA’s 21 CFR for conveying unpackaged foodstuff.

If you want to know anything about flat belts, just reach out to our experts.

To the contact form

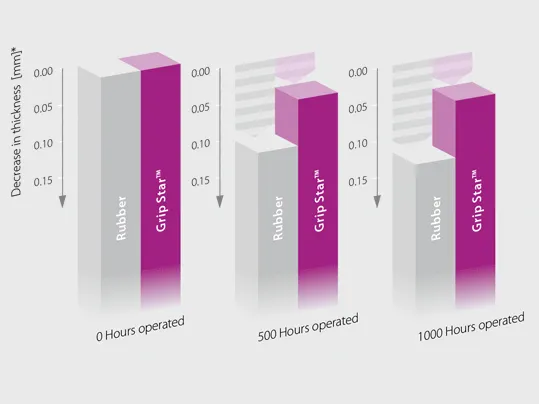

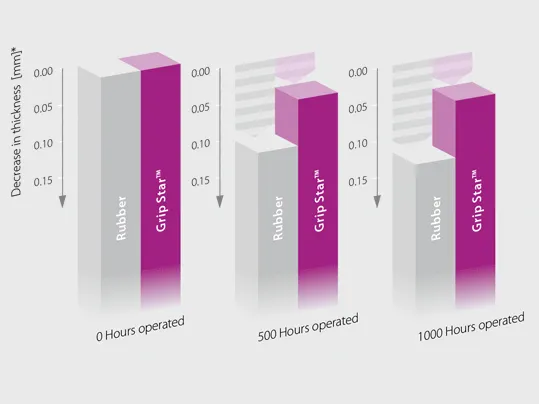

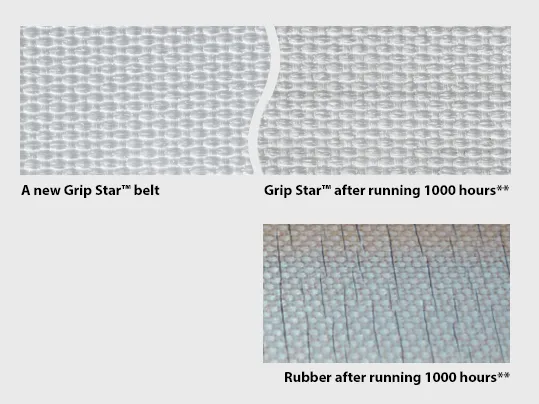

The decrease in thickness of the Medium Grip coating is significantly lower than that of rubber.

* Established in standardized testing conditions.

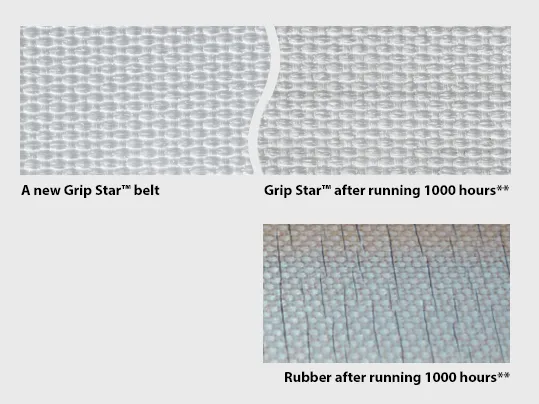

The pattern on the Medium Grip coating doesn't wear off and the surface characteristics virtually don't change. In contrast to rubber, the surface doesn't tear.

** Established under standardized testing conditions.

Sophisticated Forbo tools and processes ensure Grip Star belts are given perfect splices:

Almost all Grip Star Medium Grip products are EU- and FDA-compliant. They can be used during the manufacture of packaging and in the process of packaging foodstuffs.

Please see the current product data sheets for specific information on designs and calculations.

To the Extremultus Product Finder

E line (with polyester tension member)

| Article number | Food compliance | Folder gluer belts | Machine tapes | Elastic food tapes | Drag belts | Live roller belts | |

| RR 4E-14 HC+ FSTR grey | 822151 | ● | ● | ||||

| RR 4E-HC+ NSTR/NSTR grey | 822154 | ● | |||||

| RR 12E-14 HC+ FSTR grey | 822156 | ● | |||||

| RR 20E-20 grey FDA | 822157 | ● | ● | ● | |||

| RR 20E-30 grey FDA | 822148 | ● | ● | ● | |||

| RR 20E-40 grey FDA | 822149 | ● | ● | ||||

| RR 20E-50 grey FDA | 822152 | ● | ● | ||||

| RR 20E-60 grey FDA | 822155 | ● | ● | ||||

| TR 20E-23 HC+ FBRC/FSTR back/grey | 822171 | ● | |||||

| UR 8E-12 HC+ FSTR green/grey | 822173 | ● | ● |

| Article number | Food compliance | Folder gluer belts | Machine tapes | Elastic food tapes | Drag belts | Live roller belts | |

| RR 10P-30 grey FDA | 855638 | ● | ● | ||||

| RR 10P-40 grey FDA | 855639 | ● | ● | ||||

| RR 14P-50 grey FDA | 855640 | ● | ● | ||||

| RR 14P-60 grey FDA | 855641 | ● | ● | ||||

| TR 5P-10 FBRC/FSTR black/green | 855649 | ● | |||||

| TR 10P-30 FBRC/NSTR black/grey FDA | 855651 | ● | ● | ● |

E line (with polyester tension member)

| Article number | Food compliance | Folder gluer belts | Machine tapes | Elastic food tapes | Drag belts | Live roller belts | |

| TR 10E black/grey | 822120 | ● | ● | ● | |||

| UR 8E-15 HC+ FSTR/NSTR green/grey | 822174 | ● | ● |

| Article number | Food compliance | Folder gluer belts | Machine tapes | Elastic food tapes | Drag belts | Live roller belts | |

| UR 20U GSTR/FSTR black/blue | 855624 | ● | |||||

| UR 40U-HC+ GSTR/NSTR black/grey | 855636 | ● | ● | ● | |||

| UR 40U-12 FSTR blue FDA | 855647 | ● | ● |

Grip Star leaves no marks and has all the benefits of rubber. However, it doesn’t include the typical disadvantages of rubber such as brittleness and cross-cracking. Due to its excellent characteristics and good value, Grip Star is the better alternative to rubber. This is particularly the case when good grip, precise positioning, high levels of acceleration and high-performance braking are required.

Grip Star is produced in High Grip or Medium Grip versions in different thickness and with specific surface patterns. As folder gluer belts, drag belts, live roller belts and machine tapes, the range’s belts fulfill exacting demands and offer a wide range of uses. The majority of the Grip Star belts comply with the (EC) regulations 1935/2004, (EU) 10/2011, as well as the FDA’s 21 CFR for conveying unpackaged foodstuff.

If you want to know anything about flat belts, just reach out to our experts.

To the contact form

The decrease in thickness of the Medium Grip coating is significantly lower than that of rubber.

* Established in standardized testing conditions.

The pattern on the Medium Grip coating doesn't wear off and the surface characteristics virtually don't change. In contrast to rubber, the surface doesn't tear.

** Established under standardized testing conditions.

Sophisticated Forbo tools and processes ensure Grip Star belts are given perfect splices:

Almost all Grip Star Medium Grip products are EU- and FDA-compliant. They can be used during the manufacture of packaging and in the process of packaging foodstuffs.

Please see the current product data sheets for specific information on designs and calculations.

To the Extremultus Product Finder

E line (with polyester tension member)

| Article number | Food compliance | Folder gluer belts | Machine tapes | Elastic food tapes | Drag belts | Live roller belts | |

| RR 4E-14 HC+ FSTR grey | 822151 | ● | ● | ||||

| RR 4E-HC+ NSTR/NSTR grey | 822154 | ● | |||||

| RR 12E-14 HC+ FSTR grey | 822156 | ● | |||||

| RR 20E-20 grey FDA | 822157 | ● | ● | ● | |||

| RR 20E-30 grey FDA | 822148 | ● | ● | ● | |||

| RR 20E-40 grey FDA | 822149 | ● | ● | ||||

| RR 20E-50 grey FDA | 822152 | ● | ● | ||||

| RR 20E-60 grey FDA | 822155 | ● | ● | ||||

| TR 20E-23 HC+ FBRC/FSTR back/grey | 822171 | ● | |||||

| UR 8E-12 HC+ FSTR green/grey | 822173 | ● | ● |

| Article number | Food compliance | Folder gluer belts | Machine tapes | Elastic food tapes | Drag belts | Live roller belts | |

| RR 10P-30 grey FDA | 855638 | ● | ● | ||||

| RR 10P-40 grey FDA | 855639 | ● | ● | ||||

| RR 14P-50 grey FDA | 855640 | ● | ● | ||||

| RR 14P-60 grey FDA | 855641 | ● | ● | ||||

| TR 5P-10 FBRC/FSTR black/green | 855649 | ● | |||||

| TR 10P-30 FBRC/NSTR black/grey FDA | 855651 | ● | ● | ● |

E line (with polyester tension member)

| Article number | Food compliance | Folder gluer belts | Machine tapes | Elastic food tapes | Drag belts | Live roller belts | |

| TR 10E black/grey | 822120 | ● | ● | ● | |||

| UR 8E-15 HC+ FSTR/NSTR green/grey | 822174 | ● | ● |

| Article number | Food compliance | Folder gluer belts | Machine tapes | Elastic food tapes | Drag belts | Live roller belts | |

| UR 20U GSTR/FSTR black/blue | 855624 | ● | |||||

| UR 40U-HC+ GSTR/NSTR black/grey | 855636 | ● | ● | ● | |||

| UR 40U-12 FSTR blue FDA | 855647 | ● | ● |