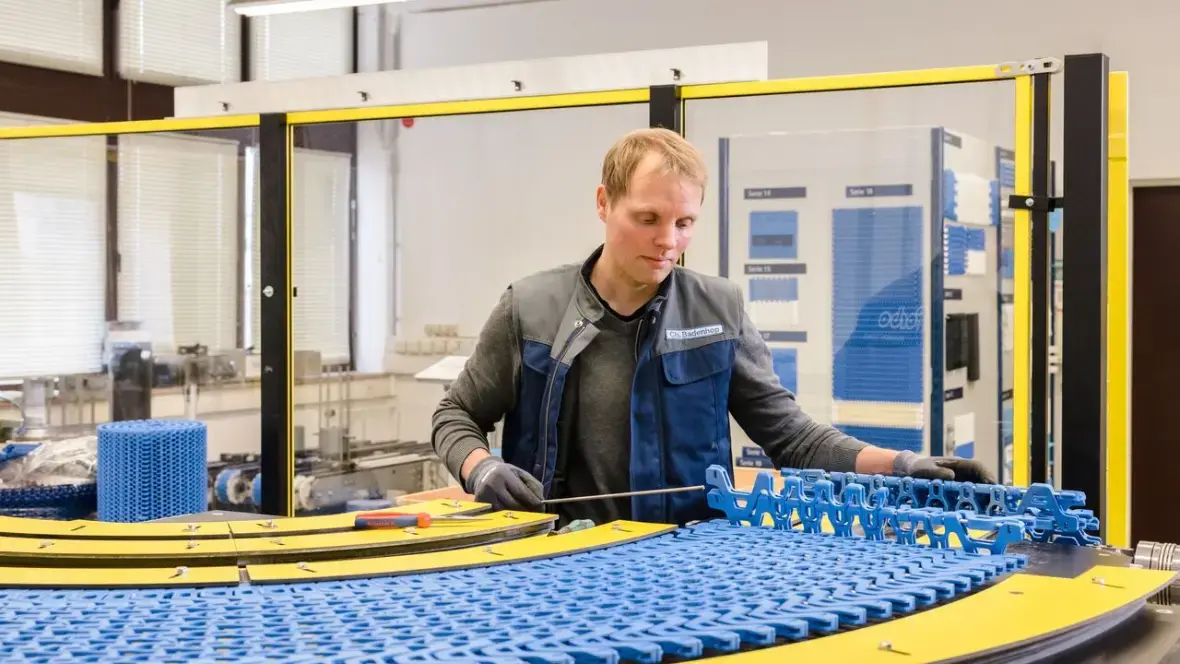

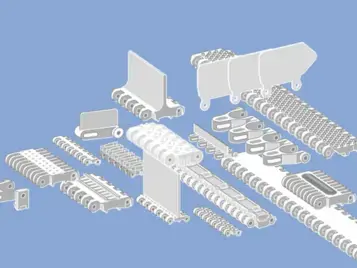

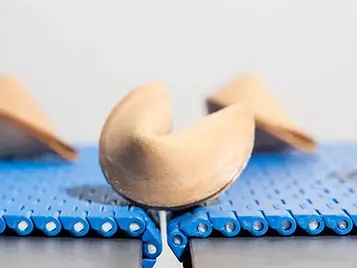

Nastri modulari in plastica di Forbo

Per una qualità superiore da parte di uno dei fornitori leader del mercato, scegliete i nostri nastri modulari Siegling Prolink ad alte prestazioni. E i vostri nastri funzioneranno in modo produttivo a costi inferiori.

.webp)

.webp)