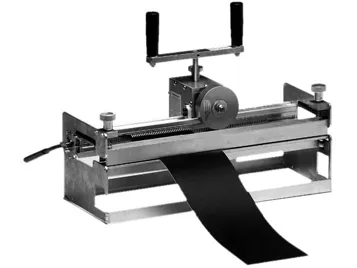

Heating press for bonded splices

SB-HP-120/50

Toolsheet (PDF | EN | 281 KB)

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

In splicing we differentiate between the three procedures: Bonded Splice Procedures, Melt Splice Procedures, Mechanical Splice Procedures

and offer the appropriate tools.

SB-HP-120/50

Toolsheet (PDF | EN | 281 KB)

SB-HP-160/100 and SB-HP-160/150

Toolsheet (PDF | EN | 277 KB)

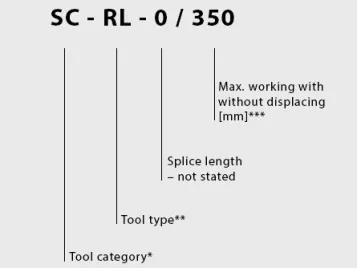

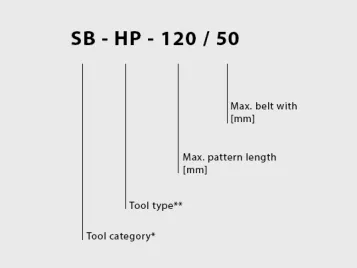

* SB = Splicing tools for bonded splices

*2 HP = Heating press

Heating tools for melt splices

In melt splices the tools are classified according to the specific applications they are used in.

Heating Clamps

Hot Presses

Special Heating Tools

Depending on the belt type, the heating tools can be used for Z-splices, Z-overlap splices, overlap splices and for splicing timing belts in different applications.

Tools for mechanical fasteners

Machine downtimes require rapid assistance.

For exchanging the belt easily and simply

Fitting tools for mechanical fasteners are used in all belts. Without dismantling parts of the machinery they are quick to insert and remove especially for belt repairs. The tools, independent of each of their working widths, are suitable for all material widths, as the belt can be moved on in the tool.

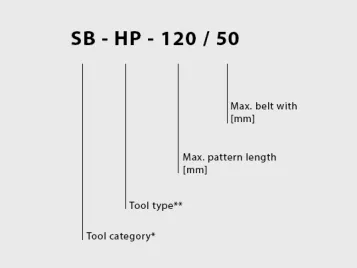

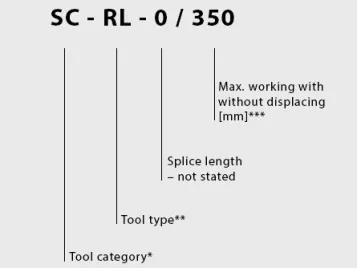

SC-RL-0/350

Toolsheet (PDF | EN | 165 KB)

* SC = fitting tools for mechanical fasteners

*2 RL = rolled splice tool

FS = comb

For the combs the additional designation means

1 = HS00, HS02, HS03, HS17, HS18, HS19

2 = HS01, HS12

3 = HS05, HS06, HS11

4 = HS09

SB-HP-120/50

Toolsheet (PDF | EN | 281 KB)

SB-HP-160/100 and SB-HP-160/150

Toolsheet (PDF | EN | 277 KB)

* SB = Splicing tools for bonded splices

*2 HP = Heating press

Heating tools for melt splices

In melt splices the tools are classified according to the specific applications they are used in.

Heating Clamps

Hot Presses

Special Heating Tools

Depending on the belt type, the heating tools can be used for Z-splices, Z-overlap splices, overlap splices and for splicing timing belts in different applications.

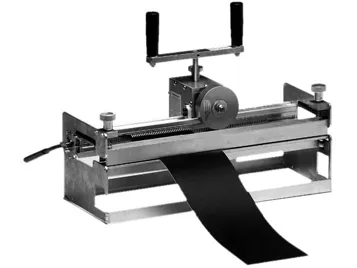

Tools for mechanical fasteners

Machine downtimes require rapid assistance.

For exchanging the belt easily and simply

Fitting tools for mechanical fasteners are used in all belts. Without dismantling parts of the machinery they are quick to insert and remove especially for belt repairs. The tools, independent of each of their working widths, are suitable for all material widths, as the belt can be moved on in the tool.

SC-RL-0/350

Toolsheet (PDF | EN | 165 KB)

* SC = fitting tools for mechanical fasteners

*2 RL = rolled splice tool

FS = comb

For the combs the additional designation means

1 = HS00, HS02, HS03, HS17, HS18, HS19

2 = HS01, HS12

3 = HS05, HS06, HS11

4 = HS09