合板製造

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

The tension member made of high-tech fabric provides a linear, steep load/extension curve. The top face has a microscopically thin, matt coating. The whole of the belt construction is very thin and is manufactured with low weight tolerances (±1%).

High levels of tensile strength, lateral stiffness, extreme resistance to diagonal warping and robust, tough designs make the two to three-ply fabric structure and the multi-ply structure so exceptional. Further advantages:

Siegling pre-press belts have a highly modular tension member made of aramide fabric with a tensile force of approx.140 N/mm at operational elongation. This means they are suitable for heavy pre-presses with nip pressure of up to 3,000 N/cm and belt pulls of up to 1,800 N/cm.

Differences in the thickness of the mat and the different levels of pull, produced as a result over the width of the belt, or radial forces that for example come about from belt tracking are compensated for by:

The new Conducto®, ventilation belt for pre-presses is based on a mixed fabric developed by GKD (Gebr. Kufferath AG, Düren) and is sold exclusively by Forbo Siegling worldwide. The fabric with polyester fibres and bronze wires (PhBz) in warp and weft is highly conductive, has a high level of air permeability and a very smooth surface. The Z-splice developed by Siegling for Conducto, is very tough and does not mark at all.

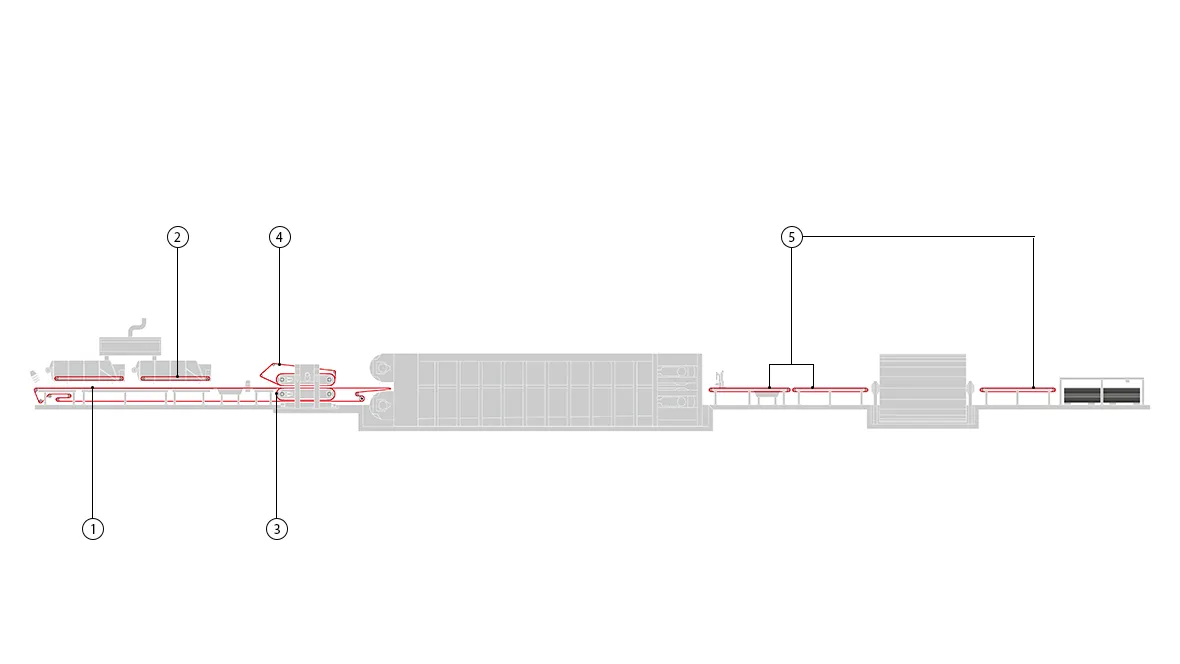

Siegling Transilon conveyor and processing belts as well as Siegling Extremultus live roller conveyor belts with different properties are used in subsequent conveying and processing of the boards. From robust "all-rounders" to real "specialists".

In conveying and in the cut-to-size sector low elongation, wear-resistance and no maintenance are a must.

Type key Siegling Transilon

Type key Siegling Extremultus

The tension member made of high-tech fabric provides a linear, steep load/extension curve. The top face has a microscopically thin, matt coating. The whole of the belt construction is very thin and is manufactured with low weight tolerances (±1%).

High levels of tensile strength, lateral stiffness, extreme resistance to diagonal warping and robust, tough designs make the two to three-ply fabric structure and the multi-ply structure so exceptional. Further advantages:

Siegling pre-press belts have a highly modular tension member made of aramide fabric with a tensile force of approx.140 N/mm at operational elongation. This means they are suitable for heavy pre-presses with nip pressure of up to 3,000 N/cm and belt pulls of up to 1,800 N/cm.

Differences in the thickness of the mat and the different levels of pull, produced as a result over the width of the belt, or radial forces that for example come about from belt tracking are compensated for by:

The new Conducto®, ventilation belt for pre-presses is based on a mixed fabric developed by GKD (Gebr. Kufferath AG, Düren) and is sold exclusively by Forbo Siegling worldwide. The fabric with polyester fibres and bronze wires (PhBz) in warp and weft is highly conductive, has a high level of air permeability and a very smooth surface. The Z-splice developed by Siegling for Conducto, is very tough and does not mark at all.

Siegling Transilon conveyor and processing belts as well as Siegling Extremultus live roller conveyor belts with different properties are used in subsequent conveying and processing of the boards. From robust "all-rounders" to real "specialists".

In conveying and in the cut-to-size sector low elongation, wear-resistance and no maintenance are a must.

Type key Siegling Transilon

Type key Siegling Extremultus