Environmental

We pull out all the stops to conduct research into, develop and improve our products consistently so that sustainability is incorporated in all our product lines and processes.

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

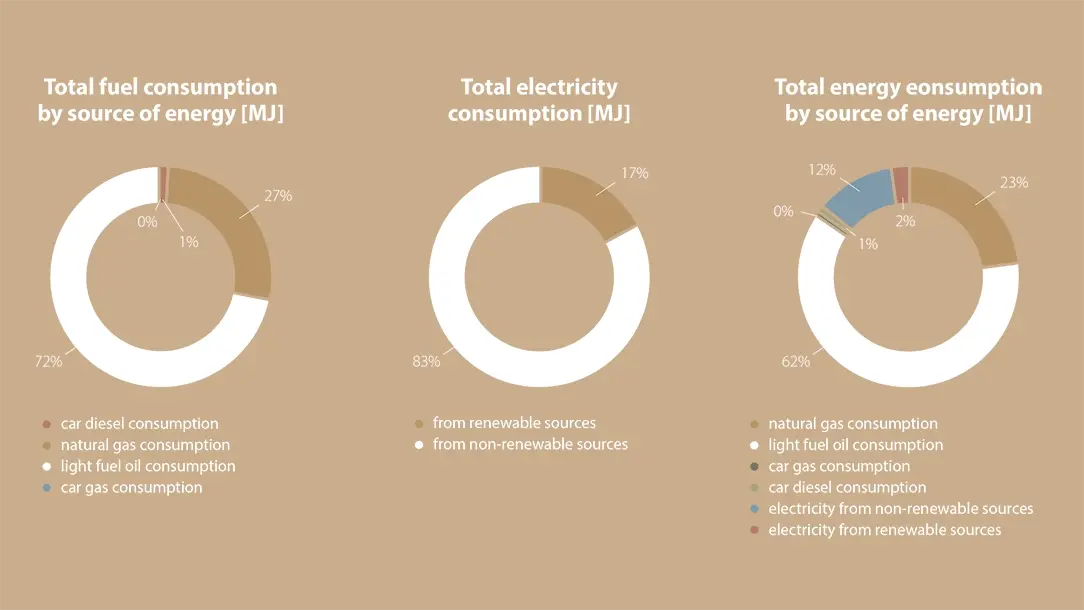

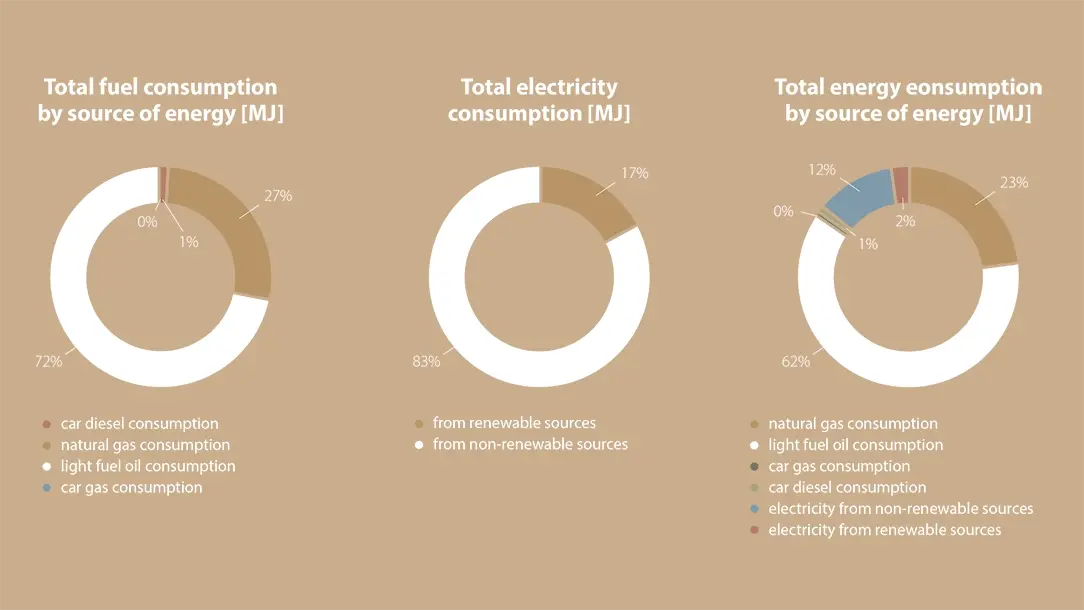

Total fuel consumption in 2022 was 882,580 MJ. Forbo Movement Systems did not use renewable fuel sources in 2022. Light fuel oil accounted for two thirds of fuel consumption.

Energy Efficiency

EN ISO 50001: The German sites are the drivers when it comes to launching an EN ISO 50001 energy management system. The goal is to cut energy consumption consistently. A dedicated energy management team develops long-term strategies to ensure this goal is achieved. Participation in the German regional network for energy efficiency and climate protection (REGINEE – REGIonale Netzwerke für EnergieEffizienz und Klimaschutz) helps us gain from the experience of other companies and vice versa. The steps we take to cut energy consumption are based on increasing awareness of the areas where consumption is caused. The improvements trialed in Hanover (Germany) and Garbsen (Germany) are in future to be transferred to other sites. New processes are also planned: these include using energy emitted from the afterburner for heating purposes and a new control system for compressed air. Our plants continuously replace illuminants by energy efficient LEDs. For instance in 2022, Germany realized an annual CO2 reduction of 35,5t by fostering the replacement of illuminants with LEDs. In our production plant in Japan and in our main Chinese plant, investments have been confirmed and planning started to realize energy efficiencies in the next few years. One aspect will be exhaust gas cleaning and using exhaust gas to operate machines. In our fabrication site in Germany and the production site in Denmark a solar power system has been ordered that is scheduled to start operating in 2023. In Denmark, two injection molding machines with frequency controlled hydraulic pumps were purchased, which have demand-based power consumption.

Environmental Management

In order to secure and structure environmental protection as a corporate goal, we launched a certified ISO 14001 environmental management system in the German and Swiss sites. All Forbo Movement Systems employees are included in this system. Certification allows for continual improvement in environmental performance.

Refusal and Reduction of Waste

Each order requires selecting a roll with the most appropriate dimensions and it needs to be cut in the best possible way to reduce wastage. To improve on the number of remnants in the fabrication process, we rolled out globally a cutting optimization tool at our fabrication sites. All our employees play a role in reducing waste, whether they work on the production line or in an office. We all contribute to the total waste produced. Digitalization projects positively impact our paper consumption in offices

Recycling Waste

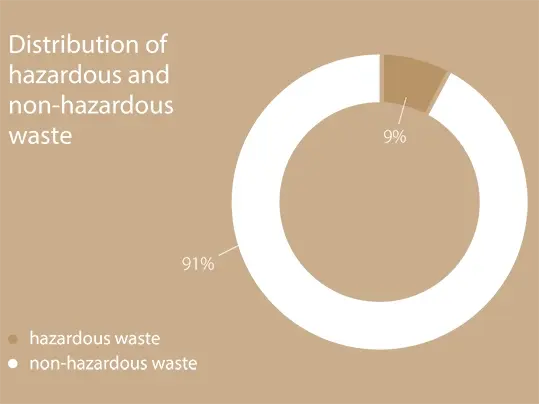

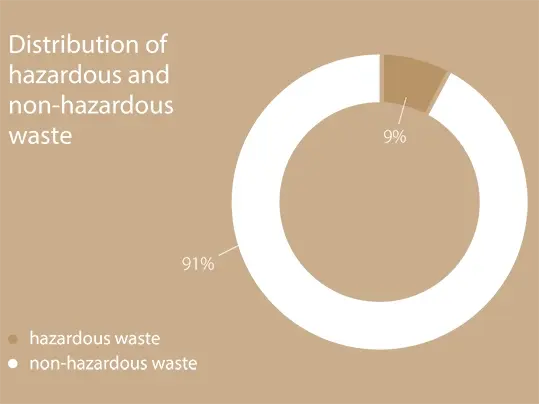

For our homogenous products in our Fullsan, Prolink and Extremultus ranges, we recycled post-industrial waste directly. To minimize production waste overall, we degranulate waste and recycle granules and include them in regular production. We aim to increase the recycling rate for postindustrial waste, but want to cut the level of production waste wherever possible. We encourage people to separate waste at our sites so that it is returned to the loop and not incinerated. Hazardous waste accounts for 9% of our total waste. We treat this waste category responsibly and continuously check whether there are nonhazardous alternatives that could be a valid replacement to reduce our share of hazardous waste.

Renewable Material Usage

Our conveyor belts are made of composite materials, which means that opportunities for including renewable raw materials in our products are limited.

Much of our packaging consists of renewable material because we use cardboard and wooden boxes to ship our products in.

Bio-Based Raw Materials

We are striving to integrate validated bio-based raw materials, such as bioTPU, bioPVC or bioPEBA in our product portfolio. We are also consistently scouting the market for bio-based alternatives and liaise with suppliers to see ways of making these materials match our material specifications.

Recycled Input Material Usage

In 2022, fabrics from recycled PET yarns used in our products were validated and we launched Transilon ECOFIBER belts made of these fabrics.

Total fuel consumption in 2022 was 882,580 MJ. Forbo Movement Systems did not use renewable fuel sources in 2022. Light fuel oil accounted for two thirds of fuel consumption.

Energy Efficiency

EN ISO 50001: The German sites are the drivers when it comes to launching an EN ISO 50001 energy management system. The goal is to cut energy consumption consistently. A dedicated energy management team develops long-term strategies to ensure this goal is achieved. Participation in the German regional network for energy efficiency and climate protection (REGINEE – REGIonale Netzwerke für EnergieEffizienz und Klimaschutz) helps us gain from the experience of other companies and vice versa. The steps we take to cut energy consumption are based on increasing awareness of the areas where consumption is caused. The improvements trialed in Hanover (Germany) and Garbsen (Germany) are in future to be transferred to other sites. New processes are also planned: these include using energy emitted from the afterburner for heating purposes and a new control system for compressed air. Our plants continuously replace illuminants by energy efficient LEDs. For instance in 2022, Germany realized an annual CO2 reduction of 35,5t by fostering the replacement of illuminants with LEDs. In our production plant in Japan and in our main Chinese plant, investments have been confirmed and planning started to realize energy efficiencies in the next few years. One aspect will be exhaust gas cleaning and using exhaust gas to operate machines. In our fabrication site in Germany and the production site in Denmark a solar power system has been ordered that is scheduled to start operating in 2023. In Denmark, two injection molding machines with frequency controlled hydraulic pumps were purchased, which have demand-based power consumption.

Environmental Management

In order to secure and structure environmental protection as a corporate goal, we launched a certified ISO 14001 environmental management system in the German and Swiss sites. All Forbo Movement Systems employees are included in this system. Certification allows for continual improvement in environmental performance.

Refusal and Reduction of Waste

Each order requires selecting a roll with the most appropriate dimensions and it needs to be cut in the best possible way to reduce wastage. To improve on the number of remnants in the fabrication process, we rolled out globally a cutting optimization tool at our fabrication sites. All our employees play a role in reducing waste, whether they work on the production line or in an office. We all contribute to the total waste produced. Digitalization projects positively impact our paper consumption in offices

Recycling Waste

For our homogenous products in our Fullsan, Prolink and Extremultus ranges, we recycled post-industrial waste directly. To minimize production waste overall, we degranulate waste and recycle granules and include them in regular production. We aim to increase the recycling rate for postindustrial waste, but want to cut the level of production waste wherever possible. We encourage people to separate waste at our sites so that it is returned to the loop and not incinerated. Hazardous waste accounts for 9% of our total waste. We treat this waste category responsibly and continuously check whether there are nonhazardous alternatives that could be a valid replacement to reduce our share of hazardous waste.

Renewable Material Usage

Our conveyor belts are made of composite materials, which means that opportunities for including renewable raw materials in our products are limited.

Much of our packaging consists of renewable material because we use cardboard and wooden boxes to ship our products in.

Bio-Based Raw Materials

We are striving to integrate validated bio-based raw materials, such as bioTPU, bioPVC or bioPEBA in our product portfolio. We are also consistently scouting the market for bio-based alternatives and liaise with suppliers to see ways of making these materials match our material specifications.

Recycled Input Material Usage

In 2022, fabrics from recycled PET yarns used in our products were validated and we launched Transilon ECOFIBER belts made of these fabrics.