A firm grip on static electricity

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

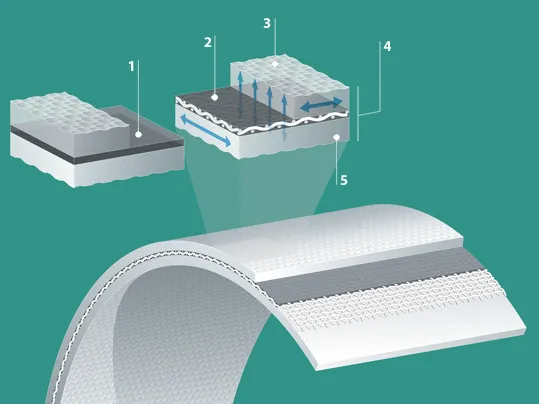

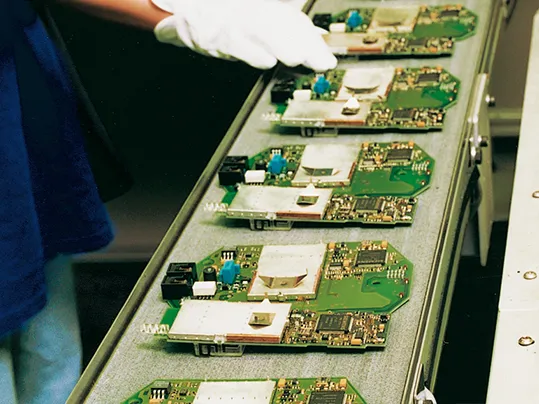

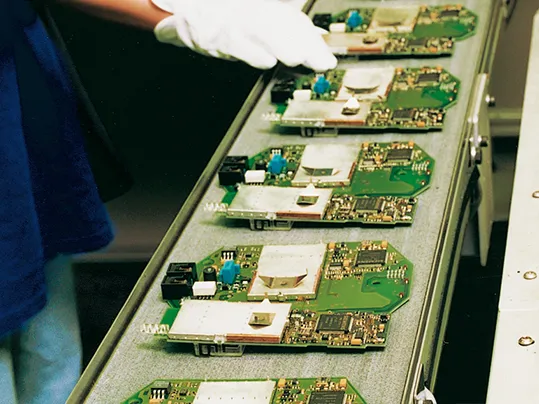

Flash Star flat belts play a major role in containing static electricity in power transmission and conveying systems. With excellent conductivity in all three directions, they help to ensure ESD (= Electrostatic Discharge) compliance of the machinery and to prevent unwelcome side effects.

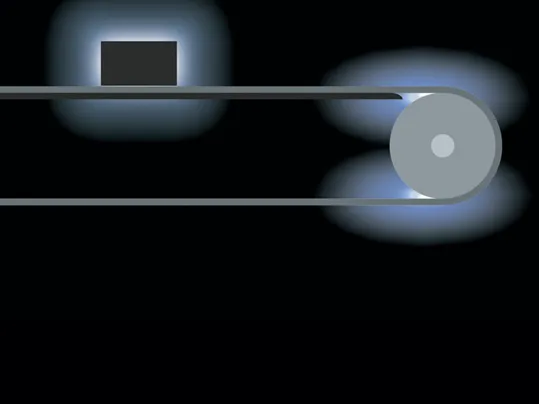

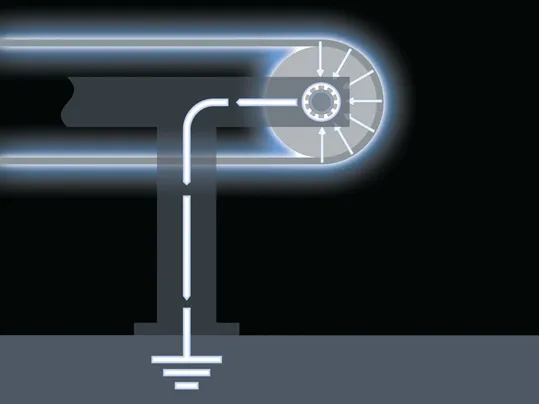

If you use power transmission and conveyor belts, it’s impossible to avoid static electricity building up. This phenomenon is called triboelectric charging. It occurs when different materials come into contact with one another and then separate again. During conveying, the products concerned can also have the same impact.

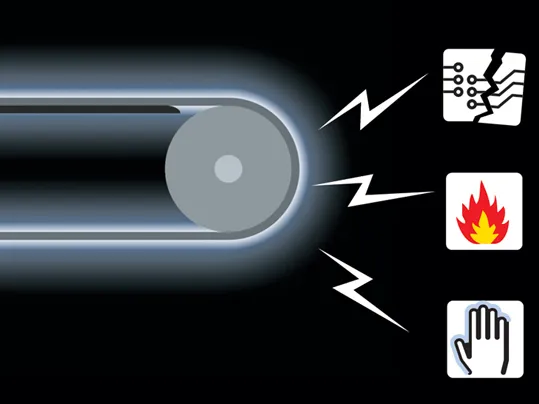

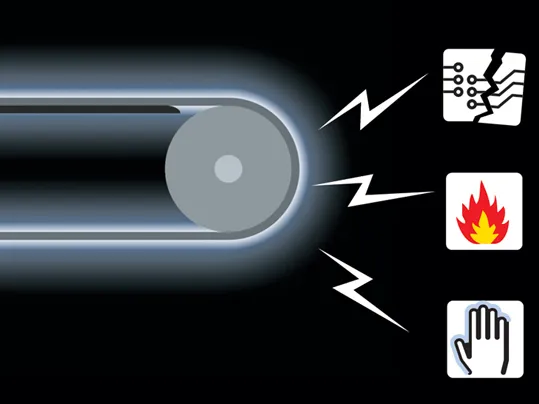

Flash Star flat belts make designing ESD-compliant machinery easier. Typical consequences of electrostatic build-up and uncontrolled discharge can be as follows:

If you want to know anything about flat belts, just reach out to our experts.

To the contact form

Electrostatic build-up from the products conveyed and due to triboelectric charging.

Hazards due to uncontrolled discharge of static electricity.

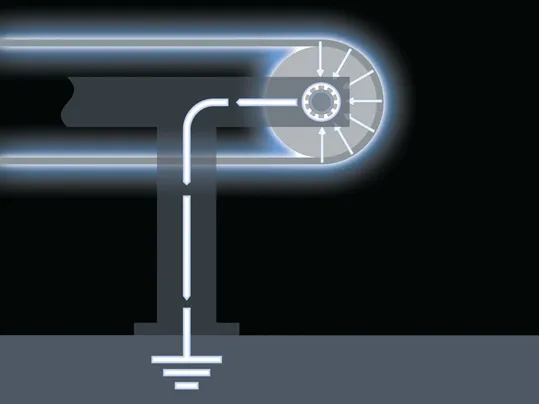

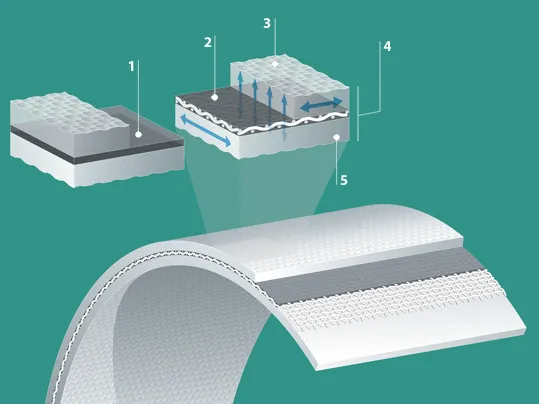

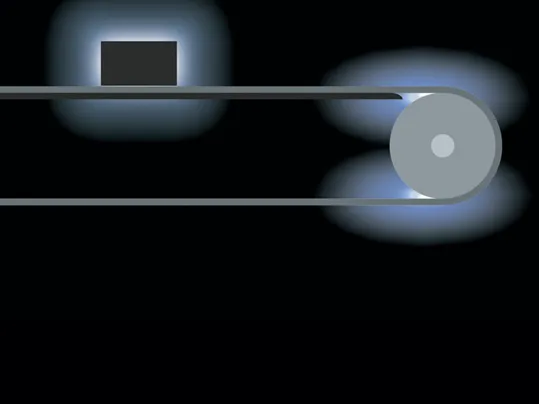

Conductivity right through the belt significantly enhances the controlled discharge of static electricity. Electricity in the belt is discharged directly via electrically conductive components on the machinery (e.g. rollers, supports). Extra mechanical components like metallic idlers, or brushes to discharge the build-up of static electricity aren’t necessary.

| The properties | The advantages |

| conductive in all three directions, even through the belt | improves discharge, facilitates ESD-compliant machinery design |

| supports the controlled discharge of static electricity | enhances process reliability and safety, e.g. for paper and foil |

| minimises the risk of uncontrolled discharge | prevents electric shocks, sparks and damage to electronic components |

| also available in High Grip and Medium Grip versions | a wide range of applications |

ESD-protected product: this product can discharge electrostatic build-up in a controlled manner. The belt’s resistance is under 109 Ω and compensates for differences in electricity potential in a short space of time.

(Measurements compliant with DIN EN ISO 21178)

| Non-antistatic (NA) |

| Belt material with isolating properties. |

| Antistatic (no special abbreviation) |

| Belt material with electrically conductive components within the belt or on the surface. Conductivity of the whole belt lengthways RDi < 3*108 Ω. |

| Highly conductive (HC) |

| Conductive top face, usually conductive underside too. Must be antistatic as well. Conductive on the surface lengthways ROB < 3*108 Ω. |

| Highly conductive plus (HC +) |

| Conductive top face, underside and through the belt too. Has to be highly conductive on both sides. Conductive right through the belt RD < 109 Ω.Flash Star |

Please see the current product data sheets for specific information on designs and calculations.

To the Extremultus Product Finder

E line (with polyester tension member)

| Article number | Folder gluer belts | Machine tapes | Drag belts | |

| RR 4E-14 HC+ FSTR grey | 822151 | ● | ● | |

| RR 4E-HC+ NSTR/NSTR grey | 822154 | ● | ||

| RR 12E-14 HC+ FSTR grey | 822156 | ● | ||

| TR 20E-23 HC+ FBRC/FSTR black/grey | 822171 | ● | ||

| UR 8E-12 HC+ FSTR green/grey | 822173 | ● | ||

| UR 8E-15 HC+ FSTR/NSTR green/grey | 822174 | ● | ● |

| Article number | Folder gluer belts | Machine tapes | Drag belts | |

| NN 4P-HC+ grey | 855635 | ● | ● |

| Article number | Folder gluer belts | Machine tapes | Drag belts | |

| UU 20U-HC+ FSTR/FSTR black | 855631 | ● | ● | |

| UR 40U-HC+ GSTR/NSTR black/grey | 855636 | ● | ● | ● |

If you use power transmission and conveyor belts, it’s impossible to avoid static electricity building up. This phenomenon is called triboelectric charging. It occurs when different materials come into contact with one another and then separate again. During conveying, the products concerned can also have the same impact.

Flash Star flat belts make designing ESD-compliant machinery easier. Typical consequences of electrostatic build-up and uncontrolled discharge can be as follows:

If you want to know anything about flat belts, just reach out to our experts.

To the contact form

Electrostatic build-up from the products conveyed and due to triboelectric charging.

Hazards due to uncontrolled discharge of static electricity.

Conductivity right through the belt significantly enhances the controlled discharge of static electricity. Electricity in the belt is discharged directly via electrically conductive components on the machinery (e.g. rollers, supports). Extra mechanical components like metallic idlers, or brushes to discharge the build-up of static electricity aren’t necessary.

| The properties | The advantages |

| conductive in all three directions, even through the belt | improves discharge, facilitates ESD-compliant machinery design |

| supports the controlled discharge of static electricity | enhances process reliability and safety, e.g. for paper and foil |

| minimises the risk of uncontrolled discharge | prevents electric shocks, sparks and damage to electronic components |

| also available in High Grip and Medium Grip versions | a wide range of applications |

ESD-protected product: this product can discharge electrostatic build-up in a controlled manner. The belt’s resistance is under 109 Ω and compensates for differences in electricity potential in a short space of time.

(Measurements compliant with DIN EN ISO 21178)

| Non-antistatic (NA) |

| Belt material with isolating properties. |

| Antistatic (no special abbreviation) |

| Belt material with electrically conductive components within the belt or on the surface. Conductivity of the whole belt lengthways RDi < 3*108 Ω. |

| Highly conductive (HC) |

| Conductive top face, usually conductive underside too. Must be antistatic as well. Conductive on the surface lengthways ROB < 3*108 Ω. |

| Highly conductive plus (HC +) |

| Conductive top face, underside and through the belt too. Has to be highly conductive on both sides. Conductive right through the belt RD < 109 Ω.Flash Star |

Please see the current product data sheets for specific information on designs and calculations.

To the Extremultus Product Finder

E line (with polyester tension member)

| Article number | Folder gluer belts | Machine tapes | Drag belts | |

| RR 4E-14 HC+ FSTR grey | 822151 | ● | ● | |

| RR 4E-HC+ NSTR/NSTR grey | 822154 | ● | ||

| RR 12E-14 HC+ FSTR grey | 822156 | ● | ||

| TR 20E-23 HC+ FBRC/FSTR black/grey | 822171 | ● | ||

| UR 8E-12 HC+ FSTR green/grey | 822173 | ● | ||

| UR 8E-15 HC+ FSTR/NSTR green/grey | 822174 | ● | ● |

| Article number | Folder gluer belts | Machine tapes | Drag belts | |

| NN 4P-HC+ grey | 855635 | ● | ● |

| Article number | Folder gluer belts | Machine tapes | Drag belts | |

| UU 20U-HC+ FSTR/FSTR black | 855631 | ● | ● | |

| UR 40U-HC+ GSTR/NSTR black/grey | 855636 | ● | ● | ● |