Plastic modular belts from Forbo

For premium quality from one of the market’s leading suppliers, choose our high-performance Siegling Prolink modular belts. And your belts will operate productively at lower cost.

With all the many applications and modular belt types, choosing the right one is often hard. At Forbo, we know what you’re looking for. We’ll help find the best solution for your production processes.

“Thanks to innovative engineering and continual improvement, our modular belts keep pace with changes. What’s more, the Siegling Prolink series are designed to meet your industry’s requirements.”

Peter Broe, Global Product Manager Prolink

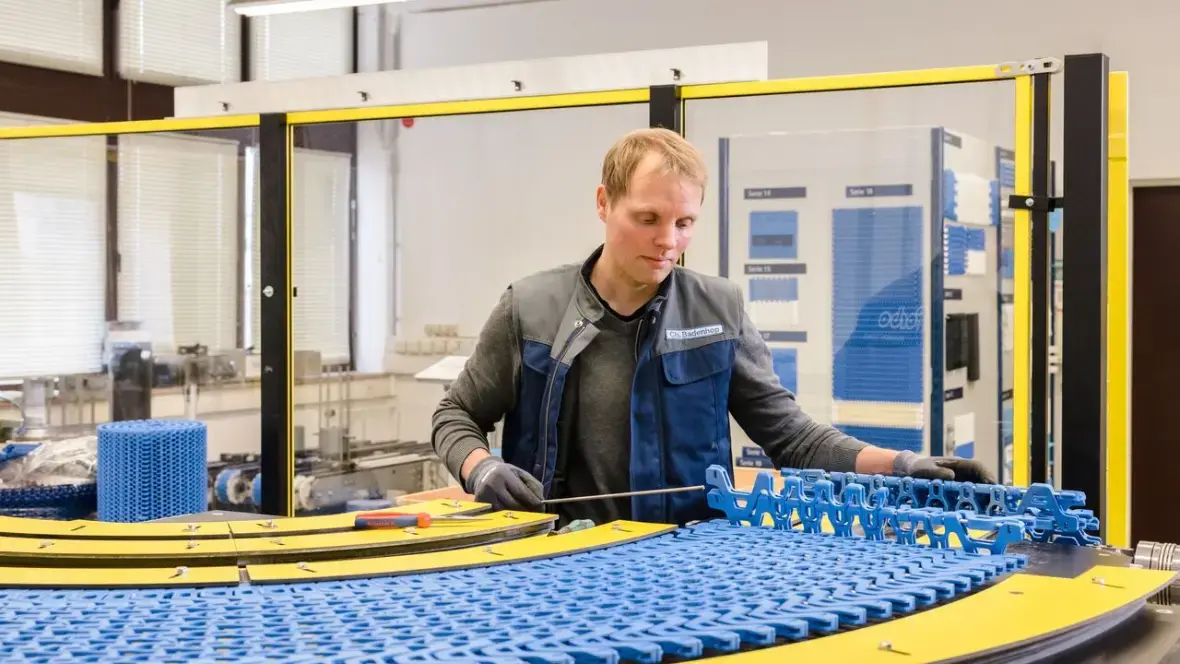

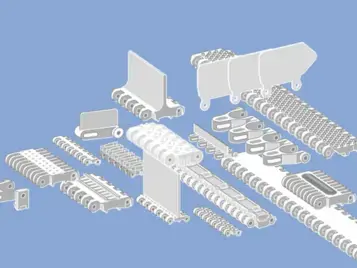

On the market since 1995, Siegling Prolink plastic modular belts are popular components in food, automotive and tire production, as well as parcel distribution centers. We’ve developed a wide range of series geared to each industry’s requirements.

Siegling Prolink belts excel in terms of reliability, performance, quality, durability, and hygiene. Our sophisticated, user-friendly solutions cut maintenance requirements and prevent unscheduled downtime.Why not reach out to us now?

18 series for any application

Dimension your conveyor

The right belt in just one click

We can help you to visualize your conveyors

Our belts in operation

Siegling Prolink

Beat the high score

Siegling Prolink applications

Arrange an appointment

How can we reconcile efficiency with responsibility for the environment? The Prolink team is happy to answer this and any other questions you might have.

Siegling Prolink is ideal for your requirements. Our belting experts explain where our belts are the ideal choice.