colorex

sd

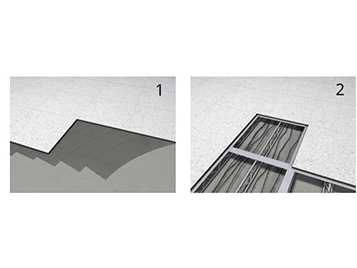

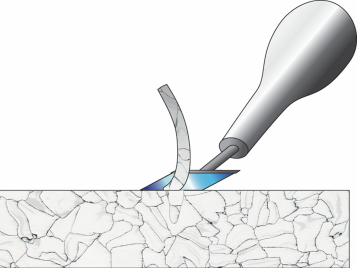

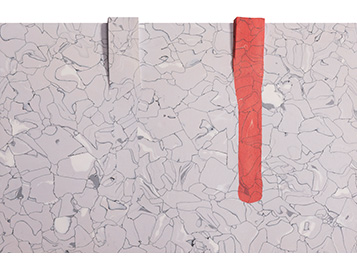

Colorex SD is a static dissipative homogeneous floor covering in tile format. The technology ensures permanent ESD properties throughout the life of the product, regardless the humidity level of the area. Because of the dense of network of conductive veins, static charges flow easily through the floor to earth.

Colorex SD can withstand and control most demanding conditions and offers a suitable solution for highly sensitive areas such as cleanrooms and for most demanding production sites in the electronics, life sciences and manufacturing industry.

SD 150201 everest

| Espessura | 2 mm |

| Comprimento / Largura | 61,5 cm x 61,5 cm |

| NCS | S 0500-N |

| Lrv | 81% |

| Recycled content | 25% |

| Renewable electricity | 100% |