Preventing showing-through in PVC and rubber floor coverings

You know it only too well – a PVC/rubber floor covering has been laid tightly and seamlessly, but then there seems to be some difference in the surface relief (see photo). This difference is especially visible in grazing light. Below you can read about how to prevent this showing-through as much as possible.

General tips

- Inform yourself in advance about the installation advice of the floor covering supplier. Every material has its own specific requirements in terms of climate, tools, etc.

- Ensure good climatic conditions, not only during, but also a few days before and after performing the work.

- Leave the PVC/rubber and adhesive to acclimatise for 24 hours in the room before use. It’s preferable to lay out the floor covering tracks separately.

- Check that the floor is levelled and at least 2 mm thick. This is done to guarantee adequate moisture extraction. If the layer is too thin, there’s a high risk of blister formation and inadequate hardening.

- Check that the surface has been sanded and vacuumed thoroughly. Remaining dust or uneven areas can result in showing-through.

- Always apply the adhesive with an A2 toothing. Use a new comb after every 40 m².

- Make sure that the PVC/rubber is placed in the semi-dry adhesive. If the adhesive is too dry, the adhesive grooves will show through.

Different methods of bonding

Showing-through is also often caused by double layers of adhesive in the middle of each track. Since each of the track halves is each treated one after the other starting from the middle, there’s often a certain amount of overlap between the adhesive layers in the middle. There are three different methods to choose from to avoid this.

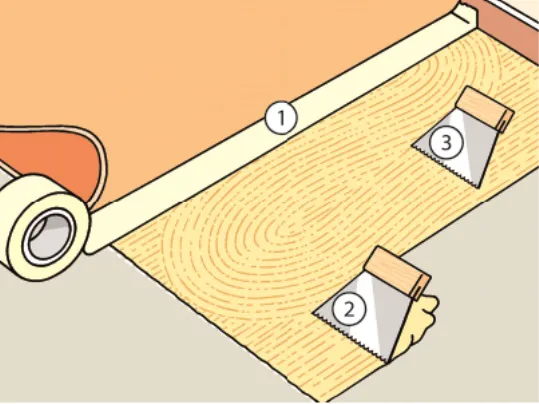

Taping off

- Draw a chalk line on the floor along the side of the PVC/rubber track.

- Pull back half of the track.

- Tape it off in the middle (1).

- Smear with adhesive, first exactly from the chalk line (2) and then over the entire surface (3).

- Remove the tape.

- Lay the PVC/rubber in semi-dry adhesive.

- Pull back the other half and smear adhesive exactly against the straight line created by the tape.

- Treat the second half in the same way as the first half.

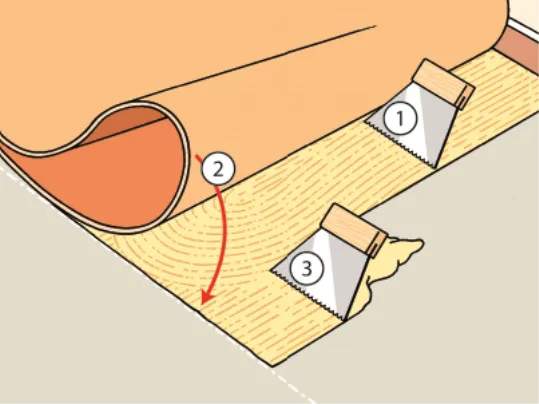

Wet in wet

- Pull back half of the PVC/rubber track.

- Smear a strip of 20 cm from the track with adhesive (1) and lay a piece of PVC/rubber directly in it (2) so the adhesive stays wet there.

- Smear the remainder of the half and leave it to become semi-dry.

- Lay the PVC/rubber in semi-dry adhesive.

- Pull back the other half to reveal the still wet 20 cm strip.

- Smear the second half of the floor (3) and let it flow over to the still wet strip.

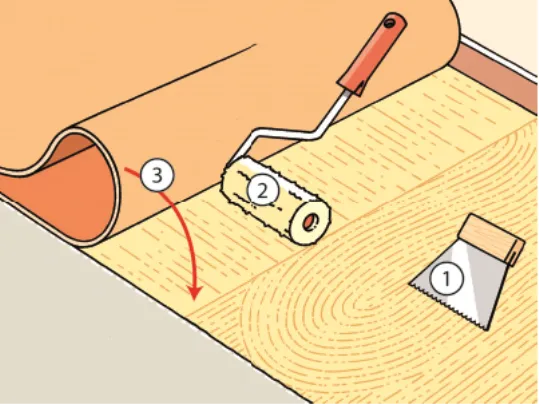

Fur roller

- Pull back half of the PVC/rubber track.

- First apply the adhesive from the middle in strips using a trowel (1) and treat it immediately with a fur roller (2).

- Then always lay the PVC/rubber directly in the adhesive in each strip (3).

- Due to the rapid drying (caused by the fur roller), it’s recommended to use two people for this method. The first person applies and then rolls the adhesive, while the second person lowers the PVC into the adhesive little by little.

Optimal adhesion without showing-through

The key to preventing showing-through is, of course, using a high-quality adhesive. In working with vapour-tight floor coverings, a long ‘open time’ is essential to be able to ‘play’ with the adhesive. The adhesive must have a high level of stickiness and final adhesion, even after it has lost its moisture.

Eurocol has developed three adhesives for this purpose:

540 Eurosafe Special is an acrylic adhesive with high spreading capacity that performs well in almost all conditions.

640 Eurostar Special also bears the ‘low-emission’ label.

In addition, when there are stringent requirements for electrical current conduction, 641 Eurostar Special EC is the appropriate product to use.