FLOORCOLOURING

levelling and concrete floor finishing in one. Tight levelling direct on colour.

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

FloorColouring is a brilliant idea. That’s because, if you can level a floor directly in the desired colour, you kill two birds with one stone. You get a beautiful, sleek floor finish and, by adding the FloorColouring pigment powder, you also create a decorative industrial look. The result is a modern floor, no two examples of which are the same. FloorColouring is suitable for indoor use, with the exception of wooden floors. Its application possibilities are virtually unlimited. FloorColouring gives a unique character to living and working spaces alike: From living rooms, kitchens and hobby rooms to offices, shops and showrooms.

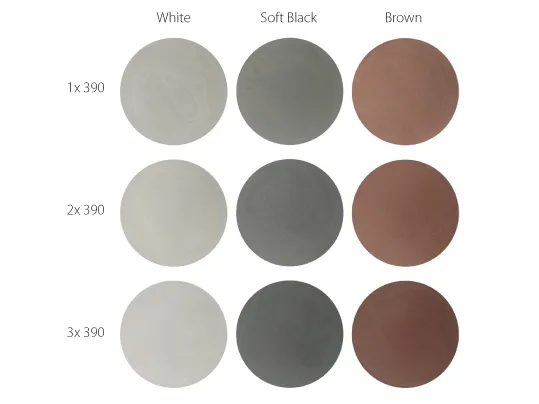

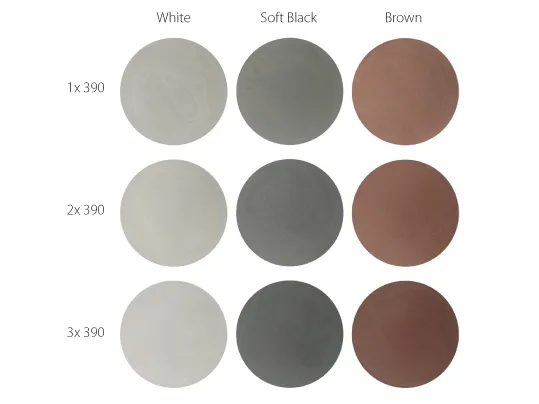

FloorColouring is available in 3 colours: Soft Black, Brown en White. All 3 colours are available in 1%, 2% en 3%.

Click here to see all the colours.

Download here the entire productrange of FloorColouring.

Download here the leaflet of FloorColouring.

You can find references and various projects relating to FloorColouring here.

FloorColouring is a brilliant idea. That’s because, if you can level a floor directly in the desired colour, you kill two birds with one stone. You get a beautiful, sleek floor finish and, by adding the FloorColouring pigment powder, you also create a decorative industrial look. The result is a modern floor, no two examples of which are the same. FloorColouring is suitable for indoor use, with the exception of wooden floors. Its application possibilities are virtually unlimited. FloorColouring gives a unique character to living and working spaces alike: From living rooms, kitchens and hobby rooms to offices, shops and showrooms.

FloorColouring is available in 3 colours: Soft Black, Brown en White. All 3 colours are available in 1%, 2% en 3%.

Click here to see all the colours.

Download here the entire productrange of FloorColouring.

Download here the leaflet of FloorColouring.

You can find references and various projects relating to FloorColouring here.