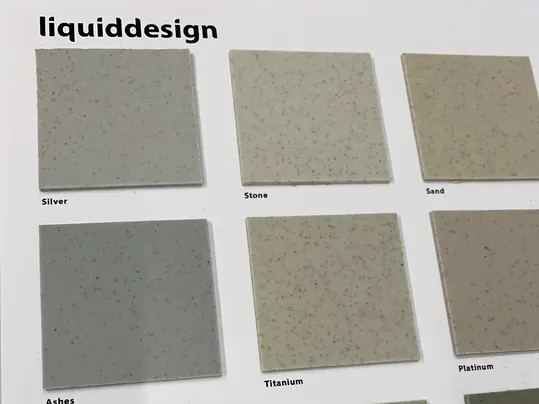

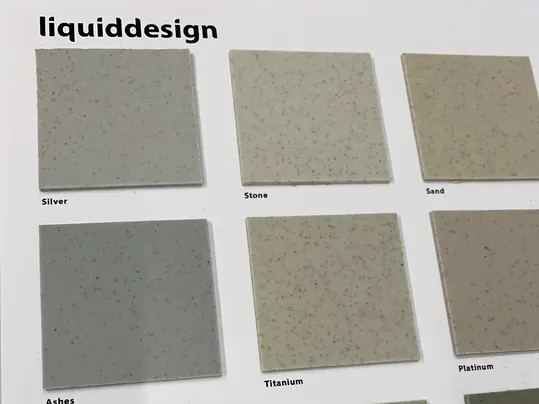

LIQUIDDESIGN

Innovative flexible liquid floor with a natural look & feel

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

Pulldown 2

LiquidDesign clearly stands out from other liquid floors like PU or epoxy. This innovative Eurocol liquid floor offers a completely different experience thanks to its permanently flexible properties, natural look& feel and aesthetic qualities. It is the result of a balanced mix of

natural components: cork, vegetable oil and biopolymer binding agent. Moreover, these natural materials are renewable, and therefore environmentally friendly.

Benefits

• warm, aesthetic and permanently flexible liquid floor

• fast and easy to apply

• seamless

• 1 coat lacquer finish without primer

• composed from natural, renewable materials

• flexible yet sturdy and wear resistant, dirt resistant and

low-emission.

• many possible applications, over 20 base colours

Click here to see all the colours of LiquidDesign.

Click here for all the LiquidDesign products.

Download here the LiquidDesign folders.

Click here to see the instruction movie of LiquidDesign.

In this video we show which steps need to be taken to create a LiquidDesign floor. NOTE: set the CC subtitle to English

LiquidDesign clearly stands out from other liquid floors like PU or epoxy. This innovative Eurocol liquid floor offers a completely different experience thanks to its permanently flexible properties, natural look& feel and aesthetic qualities. It is the result of a balanced mix of

natural components: cork, vegetable oil and biopolymer binding agent. Moreover, these natural materials are renewable, and therefore environmentally friendly.

Benefits

• warm, aesthetic and permanently flexible liquid floor

• fast and easy to apply

• seamless

• 1 coat lacquer finish without primer

• composed from natural, renewable materials

• flexible yet sturdy and wear resistant, dirt resistant and

low-emission.

• many possible applications, over 20 base colours

Click here to see all the colours of LiquidDesign.

Click here for all the LiquidDesign products.

Download here the LiquidDesign folders.

Click here to see the instruction movie of LiquidDesign.

In this video we show which steps need to be taken to create a LiquidDesign floor. NOTE: set the CC subtitle to English