Conveyor Belts and Processing Belts

Siegling Transilon conveyor and processing belts ensure efficient flow of materials and economic work processes in light materials handling.

Siegling Transtex conveyor belts are particularly suitable for demanding mechanical loads.

Conveyor Belts

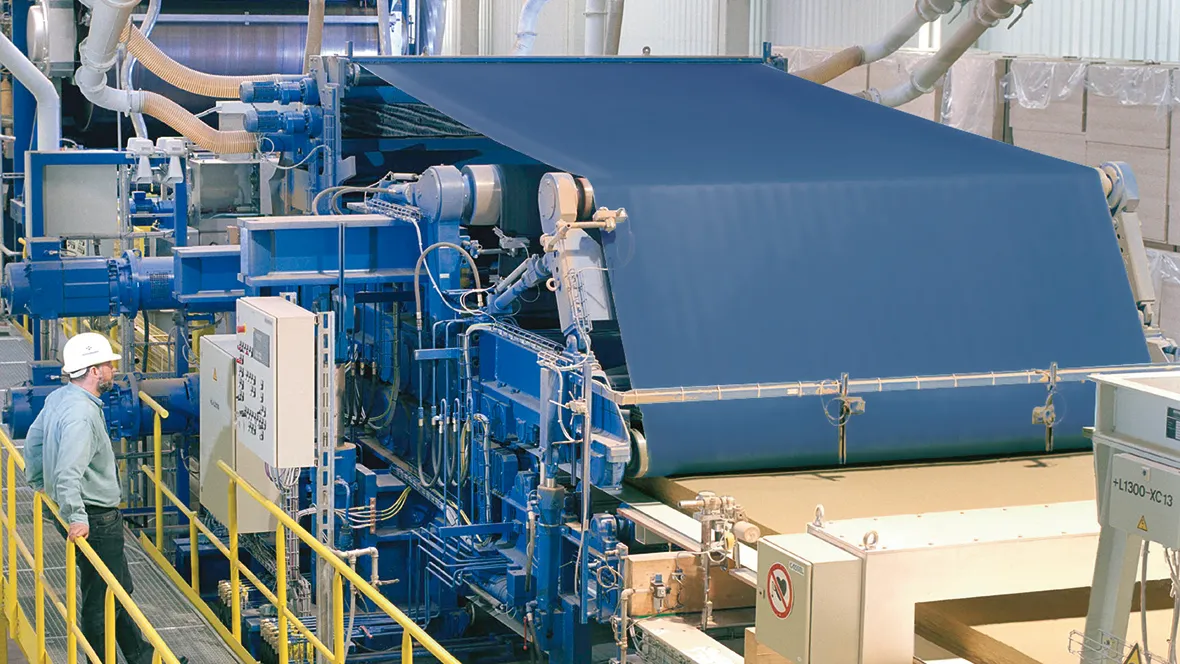

Conveyor belts from Forbo Movement Systems, also called transport belts, are an important component in all stationary and mobile conveyor systems. They are one of the crucial system components in demanding production and conveyor processes. Whether it's collecting or distributing, with inclined or curved conveying: Forbo conveyor belts have mechanical, physical and chemical properties. The belt can only have these properties through special production processes, material combinations or finishes.

In almost all industrial sectors, Forbo conveyor belts play a central role in innovative and efficient concepts for production, material flow and logistics. Numerous different belt coatings and structures as well as customer-specific finishes optimize the conveyor belt for the diverse needs of our customers. The construction of our fabric belts is consistently geared towards market requirements, many products are based on joint development work with users and OEMs. We only use the highest-quality raw materials to manufacture our fabric-based conveyor belts.

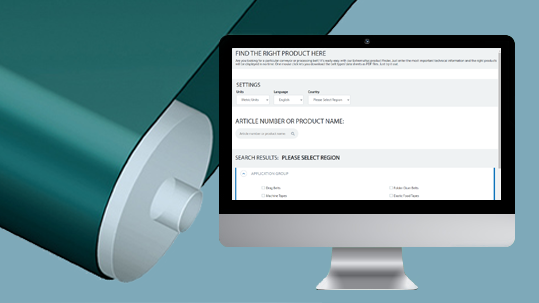

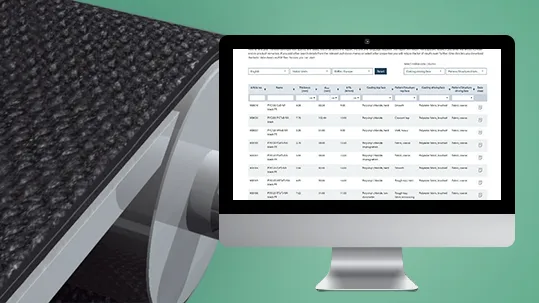

Find the right conveyor belt for your application, quickly and easily

Processing Belts

Whenever there is an automated processes, processing belts from Forbo Movement Systems are a very good choice. Siegling Transilon processing belts bridge the shifting boundary between classic conveyor function from “A” to “B” and contributing actively to the production process.

In the textile industry our processing belts layer wafer-thin fleece layers, in industrial bakeries they shape dough pieces, in the wood industry they compress the chip mat in the pre-press, in dairies milk is coagulated to cheese on the belt. These are just a few examples of “process functions”.

The most varied belt properties such as good release properties, high level of resistance to oil and grease, resistance to hydrolysis or ease of cleaning safeguard our customers’ process chain and guarantee the highest product quality. With our expert knowledge we understand the specific applications and develop reliable, long-lasting solutions by working with our business partners.