eurocol

692 JOINTING CEMENT

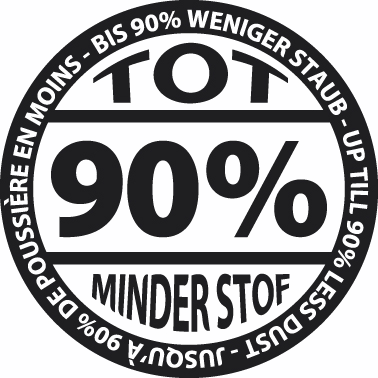

Grouting cement for ceramic floor tiles.