5. Recycling & end of life

Recreating value at the end

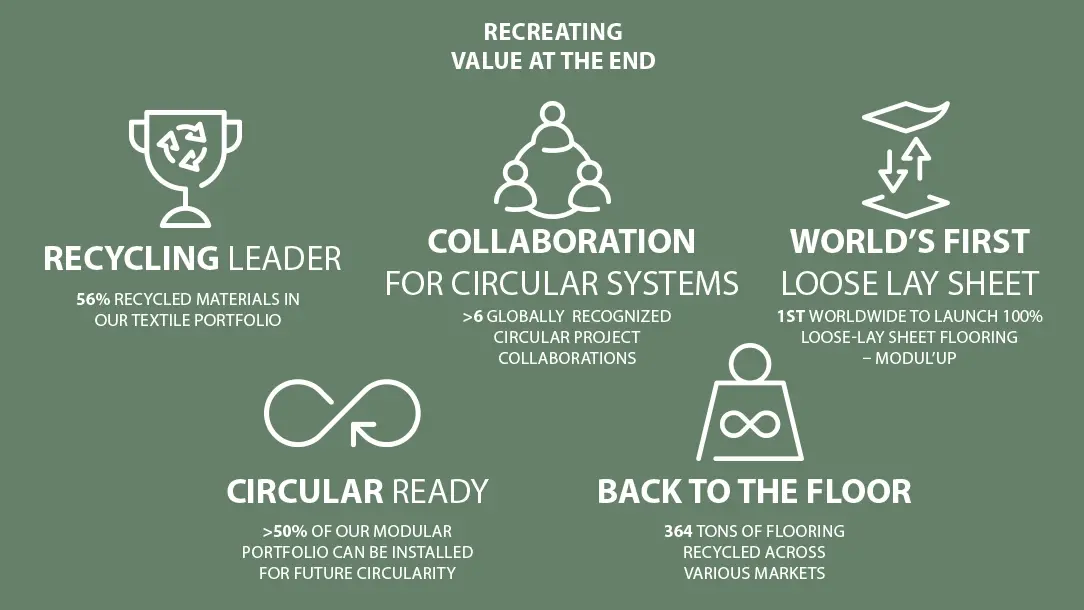

RECREATING VALUE AT THE END

We want to lay the foundations for a better future. That means building on the foundations of the past.

To make flooring circular, we need to change our collective mindset from end-of-life to end-of-one-life. In that way we are creating flooring solutions that have the lowest environmental impact.

Start at the beginning

Our short-term goal is to re-use or recycle 95% or more of product waste.

The fifth and final of our key challenges is all about recreating value at the end of the cycle. Our goal is to re-use or recycle 95% or more of our product waste and to actively contribute to the leading local recycling schemes worldwide to keep materials in use.

To ensure that we are able to recreate value at the end, we start at the beginning: we design products with circularity and users in mind. We make our flooring solutions durable and fit-for-purpose.

Every year our circular-ready flooring offering is expanding. Loose-lay installation, for example, makes it possible to take back used products without contamination of glue and screed, making products easier to re-use or recycle.

Transparency

Dealing with the legacies of the flooring industry

Giving a new purpose to materials that would otherwise be disposed of can be challenging. Being climate-conscious with post-installation residue and used flooring systems can seem expensive and difficult and is not always transparent.

But we have to be transparent. No flooring manufacturer has been able to collect and repurpose flooring residues on the scale that is needed. We have to deal with the legacies of the flooring industry, which sadly was, back then, not designed for circularity. This is an obstacle we need to overcome before we can take back and recycle everything we produce.

How we deal with our waste

Recycling is not always an option

We are not trying to recycle all flooring waste within our own products. That might sound strange, but sometimes we simply can’t yet, and sometimes it is even irresponsible to do so.

There are many ways in which we are currently dealing with residues:

• Working with raw material suppliers for centralised recycling. For example, chemical recycling for vinyl is being explored.

• Using materials in our own production, such as post-consumer linoleum, vinyl scrap etc.

• Working with customers to extend floor life or renovate flooring.

• Collaborating with external parties for solutions. For example: some linoleum waste is used as filler in the cement industry.

• Working with waste management companies, for example by researching biodegradation or otherwise extracting as much energy as possible through incineration.

Our challenges

We do not have all the solutions in place yet

We have to take local conditions into account

Material composition limits recycling

Few industry initiatives & collaborations

Back to the floor

Setting up local recycling programs

Until flooring can go fully circular on a global scale, we have started developing solutions on a regional scale by actively offering installation waste take-back programs in instances where this is the most sustainable option, taking into consideration the carbon footprint of the necessary logistics. This way we can get round current limitations and move forward in preparation for tomorrow.

Back to the Floor programs are currently already running in Sweden, France, the Netherlands, UK and USA.

In 2021 we collected and recycled:

-

40

tons of linoleum

-

317

tons of vinyl

-

7

tons of textile