Confectionery

Sticky and greasy products such as chocolate of all types, or wine gums, primarily require special top-face coatings or surface patterns during production.

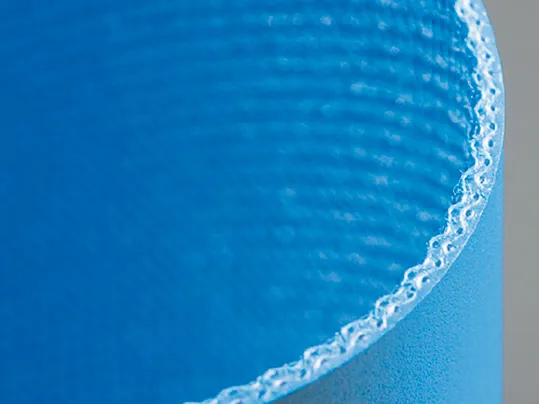

Due to the special design of Forbo’s Frayfree belts, virtually no fluff forms on the edges of the belt. A special type of fabric and weave as well as an enhanced filament length, ensures that no problems are caused by the unsealed belt edges. The versatile product range is suitable for a wide variety of applications and perfectly fulfils the stringent demands of the food industry.

Ref. No. 246 | Issue 02/20

PDF | EN | 167 KB

Forbo’s Smartseal belts prevent oil, grease and water and hence bacteria from penetrating the carcass of the belt. At the same time they prevent fluff from protruding at the edges. With high demands for hygienic conveyor belts made of synthetic materials and fabric tension members, our Smartseal belts are some of the best options.

Ref. No. 247 | Issue 03/17

PDF | EN | 145 KB

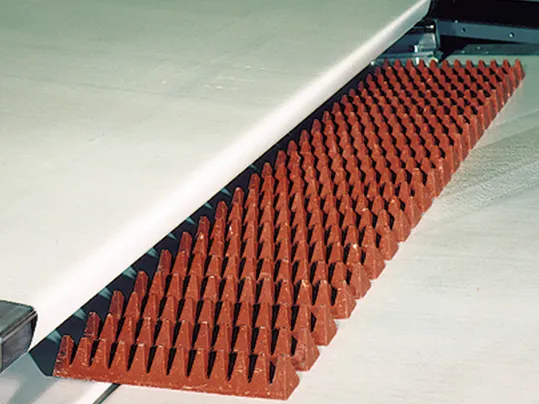

Gentle and effective cleaning of belts with urethane scrapers. In contrast to rigid scrapers made of metal or hard plastic, Forbo scrapers are not just gentle to the surface of the belt, but to the splice too. The wear resistant scrapers come in different colours and as metal-detectable (MD) types.

Article No.: 882156 | Issue 04/18

(PDF | EN | 213 KB)

Article No.: 882155 | Issue 04/18

(PDF | EN | 207 KB)

Article No.: 882228 | Issue 04/18

(PDF | EN | 176 KB)

Article No.: 880137 | Issue 04/18

(PDF | EN | 207 KB)

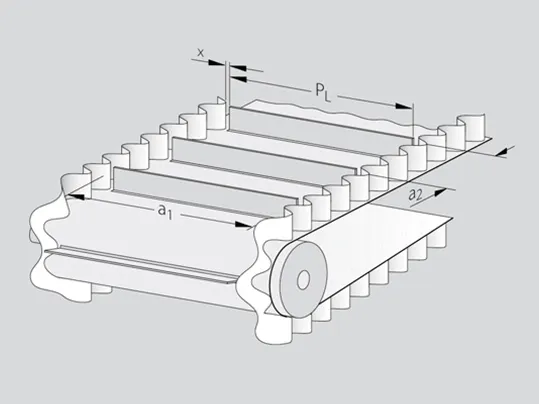

We offer a range of sidewalls, developed for the requirements of the food industry, for inclined or steep conveying of confectionery, flour or sugar for example. Their high level of resistance to oils and grease, as well as cleaning agents and disinfectants, guarantees safety all along the line.

Ref. No. 120 | Issue 08/12

PDF | EN | 204 KB

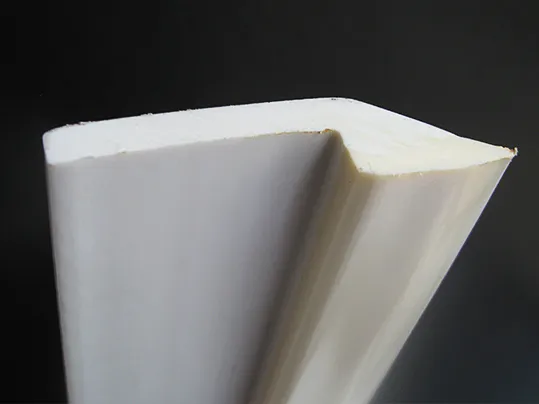

A special design gives Forbo cutting belts an exceptionally high level of resistance to incisions while still providing excellent results when cutting the products. Due to the superb durability, these HACCP belts are also a superior, economical product.

Ref. No. 300 | Issue 11/22

PDF | EN | 200 KB

HighGrip is a special type of surface coating that ensures perfect product grip, easy splicing methods and a very strong top face. HighGrip belts are especially suitable for inclined conveying.

Ref. No. 191 | Issue 02/12

PDF | EN | 348 KB

Release characteristics depend on the physical nature of the top face, the top-face pattern and the type of products conveyed (greasy or watery). Coating materials with little surface tension have a natural anti-adhesive effect and are therefore a good choice for conveying sticky, sugary products. Special surface patterns influence product release. For any kind of product Forbo Movement Systems can offer a conveyor belt with the most appropriate release characteristics.

Ref. No. 204 | Issue 04/11

PDF | EN | 230 KB