Defining natural spaces

Our new Marmoleum Marbled flooring presents the classic marbled pattern in 5 intriguing organic structures; Real, Fresco, Vivace, Splash & Terra. This sustainable linoleum floor covering offers the largest resilient flooring color bank. The different patterns can be effortlessly mixed or used alone.

Why choose Marmoleum Marbled flooring?

MADE BY NATURE

● Marmoleum is manufactured from natural raw materials

● Low in emission, free from plasticizers and synthetic additives

● The Marmoleum product range is a climate positive floor covering solution (from cradle to gate). Read more about it here

● Made to contribute to a healthy indoor environment

INSPIRED BY NATURE

● Largest resilient flooring color bank. See the complete color overview.

● The soft, natural feel of Marbled coordinates well with woods and stones

● Its blend of colors provides versatility when combining with other surfaces

● The different patterns can be effortlessly mixed or used alone

● Intriguing organic structures

RELIABLE BY NATURE

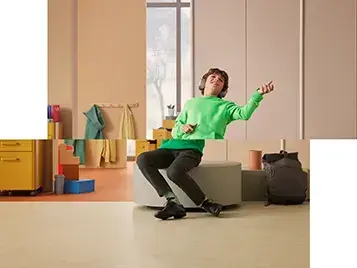

● Versatile in its application, durable in use

● Easy to install with net fit seam technology

● Easy to clean and good appearance retention

● Reliable, based on proven performance of millions of m2 installed worldwide

Application areas

Because of its special characteristics Marmoleum Marbled flooring is an excellent flooring choice for almost all application areas, like healthcare flooring, school floors, hospitality flooring, retail floors and so on.

Acoustic linoleum

Marmoleum Marbled is offered as acoustic flooring Marmoleum Decibel, offering 18db and 14dB sound reduction.

Marmoleum Fire retardant

For those areas where extended fire retardancy protection is required, Forbo has developed 2.5 mm Marmoleum FR. This new variant has an improved reaction to fire classification: Bfl-s1, G, CS according to EN 13501-1.

Marmoleum FR is also classified as a D-s2, d0 wallcovering in accordance with EN 15102. Marmoleum FR is available on request and minimum order quantities and lead times apply. Please contact your local sales organization for more information.

.webp)