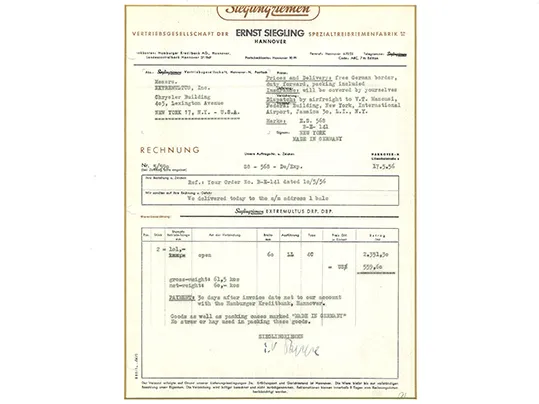

Invoice for the first two Extremultus power transmission belts as delivered in 1956 from Hannover, Germany to Extremultus, Inc., N.Y.

Forbo Siegling, LLC Celebrates a 60 Year Milestone

60 years ago, a very significant strategy was launched in the US. It involved two parties, Ken Sonotta and Dr Gerd Hofmeister. One was American, and the other German, both with a common interest in developing power transmission belting sales in the US. Siegling was well known in Europe as the leader in leather power transmission products selling and marketing under the Extremultus Brand. Both agreed that launching the product in the US would offer opportunity for both parties.

The US relationship actually first started in April, 1955 when the first orders were gained from Air Reduction located in New York. Even though sales volume grew very slowly that first year, it was clear that the US offered potential for growth if the leather-backed Extremultus belts could perform well on heavy duty air compressors, wood product chipping, and paper factory machines.

Both gentlemen agreed to a cooperation, and the birth of Siegling in the US began May 1, 1956 on Long Island, New York. Sales volume in the first year was USD 76,082.78. Within a very short time business prospered and the company then moved to Englewood, New Jersey where it continues to serve the northeastern United States market even today.

During the early years in the US sales expansion was consistent, branch locations around the US developed and in 1990 the decision was taken to manufacture Transilon product in Huntersville, North Carolina. In 1994 with the new factory in place, US headquarters relocated from Englewood to Huntersville and sales growth increased dramatically. By August, 2000 the Huntersville factory was operating on a 7 day/ 24 hour basis.

Today, Forbo Siegling is comprised of many long term employees (14 years average), and 7 fabrication/service center locations geographically placed around the US. The development of extraordinary service capabilities has enabled dramatic growth, and customer dependence on our technology in many industries from food, to logistics, to industrial production is ever increasing.

As we reflect on the History of the US operation, I feel the most important ‘Forbo Way to Win’ characteristic of employees is ‘Caring’. Today we have nearly 400 employees, who routinely focus on the varied needs of our many customers. Fabrication generates almost 1.0 million individual belts each year supporting the US market with a quality focus that is now highly respected, and highly anticipated. We recently achieved the milestone of producing 500,000 belts to a key customer without any splice issues, a fact that is valued by the customer in routinely dealing with Forbo Siegling, LLC. Our employees are a combination of seasoned experience and relatively new, but vibrant youth who combine to provide reliable service to our customers.

One factor that all are aware, the next 60 years will continue to see many changes, but focus on quality by caring employees provides confidence to all involved.

Contact: Wayne Hoffman, President

Forbo Siegling, LLC

Sales and Fabrication team at Long Island office and workshop in 1956

When Extremultus, Inc moved to Englewood, NJ, then becoming Siegling America

CMC facility in Huntersville