Connect with modern nature

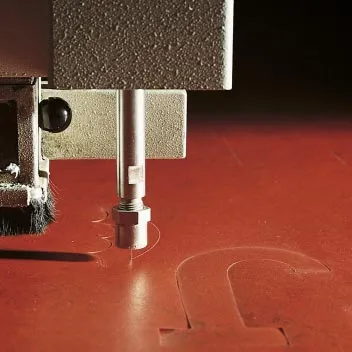

Marmoleum brings a touch of nature in our daily lives and reinforces our connection to the environment.

Marmoleum connects with modern nature through climate positive flooring and contributes to each and everyone’s well-being on many levels. An endless source of inspiration, from the natural materials we use to the colours and designs we offer. Together with nature, we have designed floors that form the foundation of comfortable and healthy spaces, where people can happily move, work, learn, heal, play and relax.

We have the flooring solution for any interior in terms of visual and colour. From the trendy muted designs in a natural colour palette from our Solid collection, to the lively marbled colours from the Marbled collection that stand out and ensure that all spaces become eye catchers and the warm linear visuals from the Linear collection that create a comfortable and homely feel.

The Marmoleum Modular collection with linoleum tiles and planks in various designs and sizes gives you all freedom to create stunning floor designs. Our Marmoleum CinchLoc tiles and planks have a special tongue & groove locking system, making your floor fun to design and easy to install.

Our extensive Marmoleum range also offers acoustic, conductive and sports flooring.

With our Bulletin Board linoleum pinboards you can create a decorative element that offers a practical solution to collect and exchange thoughts and ideas.

Furniture Linoleum is a unique surfacing material for furniture applications. The material is naturally flexible and can be applied to all types of furniture.

We invite you to create sustainable spaces that have a positive impact on everyone and everything.