Sustainable belting solutions

Committed to making a difference.

Commitment

OUR AMBITION – OUR WAY

We deliver quality

As a global leader in the belting industry, we are committed to sustainability, reliability, and innovation, striving to create high-quality conveyor belts while minimizing environmental impact and preserving resources for future generations.

Driving sustainability with passion and innovation

Sustainability is at the heart of everything we do. It guides our business decisions and inspires impactful industry-wide initiatives through collaboration and leadership. With an innovative mindset and a hands-on approach, we combine passion with interdisciplinary expertise to make a lasting difference.

Our global activities are geared towards all three dimensions of sustainability:

-Environmental

-Social

-Governance

.webp)

DIMENSIONS OF SUSTAINABILITY

HOW WE ACT

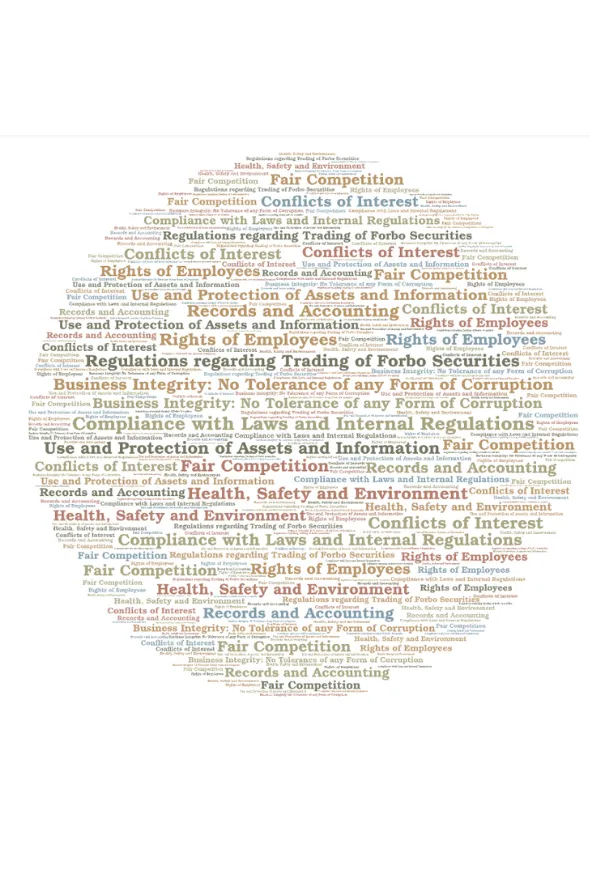

Code of Conduct

A strong commercial base is vital to developing a sustainable organization. Our goal is to consistently deliver innovations and optimize the design, service level, performance, range, and quality of our portfolio for all stakeholders. We act responsibly and within our corporate governance, risk and crisis management guidelines, and our Code of Conduct. We always respect local and international laws and regulations.

Forbo’s Code of Conduct applies to all employees. It clearly states that the company does not engage in or tolerate any dubious or corrupt practices. The Code is part of the mandatory Forbo training program. It sets out our most important business principles and basic values. Read more about the Forbo Code of Conduct. If Forbo should ever fall short of these values, we encourage all employees to report it via the Forbo Integrity Line.

Values and Mission

As a global market leader in the belting industry, we offer our customers first-class solutions to keep their business success on track. Our commitment and expertise offer promising prospects to our stakeholders.

Through our worldwide presence with 300 service locations, we aim to maintain and expand our position as a global player. We are convinced that quality and its continuous improvement are key to this. This is expressed both in our high-quality and economical products and in our competent and customer-oriented advice. We behave consistently in the same way as we would like our environment to behave: as a reliable partner.

.webp)

Certifications

Movement Systems documents process conformity and compliance with these standards with its ISO certifications for quality management (ISO 9001), environmental management (ISO 14001) and energy management (ISO 50001).

ISO 45001 certification in 2024, we achieved the internationally recognized health and safety certification at two sites. In future, this will allow us to act even more professionally within an official health and safety management system.

QUALITY MEANS SUSTAINABILITY

That is why we only use selected raw materials for the manufacture of our products, rely on our trained and experienced staff in production, assembly and administration and supplement proven manufacturing processes with state-of-the-art technology. This is how your premium belting product is created. It is high quality and durable. Because that is sustainable.

How we make a difference

Discover what we do to become the most sustainable belting manufacturer

Transilon ECOFIBER - Conserve resources

Read more

Transilon ECOFIBER’s tension member fabric is made exclusively of

recycled PET bottles. As a result, we save valuable resources during its manufacture, without compromising on quality or durability. At the same time, we cut energy consumption and carbon emissions significantly.

Just like our tried-and-true AmpMiser types, we can upgrade the underside fabric by adding Texglide, which is patented

Amp Miser – Safe energy

Read moreAmp Miser energy-saving conveyor belts are engineered to significantly reduce friction where energy losses are highest: between the belt’s underside and the slider bed. With our patented Texglide layer applied to the underside fabric, the belts feature a low-friction, self-lubricating surface that minimizes energy consumption. This benefits the environment by reducing CO2 emissions.

Extremultus – Benefit from high effiency

Read moreDrag belts are special developments with exceptional mechanical and electrostatic characteristics that make conveying and handling electronic components safer and more efficient. Easier accumulation with the one of the latest belt versions, which has consistently low friction coefficients on the top face and underside, means energy savings of up to 50% compared with standard types.

BioBelt– Decide eco-friendly

Made of 20% or more renewable raw materials, BIOBELT is the eco-friendly alternative

to traditional conveyor belting that can easily replace standard belts in many applications. Developed by a global team of researchers, BIOBELT is the right choice for any conveyor operators who adopt more than just a sustainability mindset, but consistently pursue a sustainability strategy.