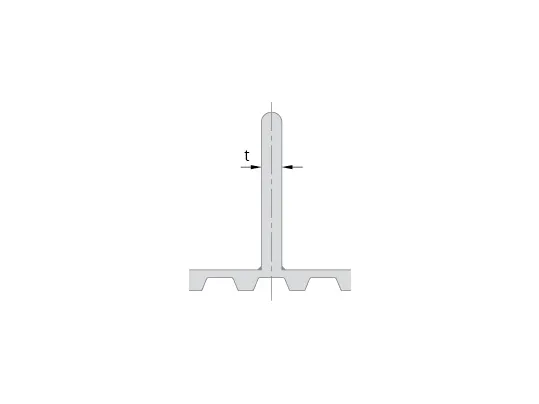

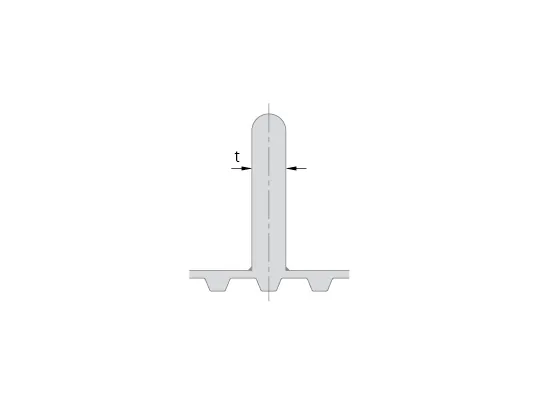

The recommended maximum cam thickness (t) is listed in the welding table according to the number of teeth on the sprocket.

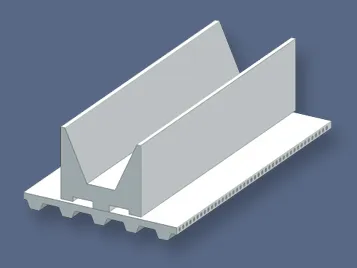

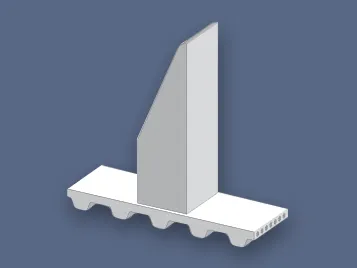

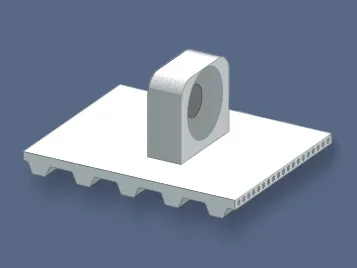

Cams

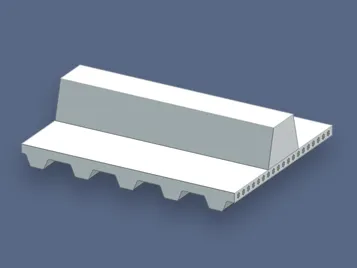

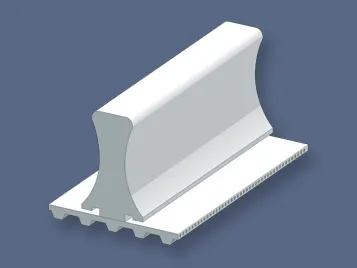

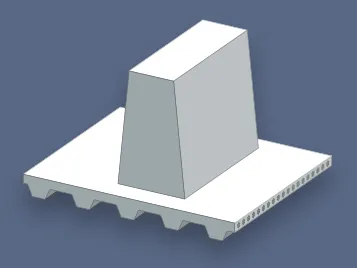

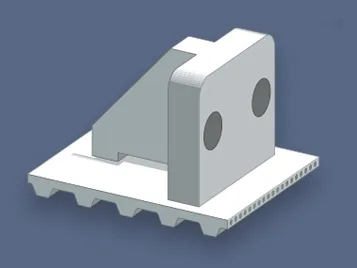

Timing belts with cams offer innovative design solutions for special duties in the material flow.

Any cam shape can be made for you.

Welding table

Maximum cam thickness in mm when welded on opposite tooth

Number of teeth on sprocket

| Typ | 20 | 25 | 30 | 40 | 50 | 60 | 100 |

| T 5 | 5 | 6 | 6 | 8 | 9 | 10 | 12 |

| T 10 | 8 | 9 | 10 | 12 | 14 | 15 | 20 |

| T 20 | 12 | 13 | 15 | 18 | 20 | 23 | 30 |

| AT 5 | 5 | 6 | 6 | 8 | 9 | 10 | 12 |

| AT 10 | 8 | 9 | 10 | 12 | 14 | 15 | 20 |

| AT 20 | 12 | 13 | 15 | 18 | 20 | 23 | 30 |

| XL | 5 | 6 | 6 | 8 | 9 | 10 | 12 |

| L | 6 | 7 | 8 | 10 | 12 | 13 | 16 |

| H | 8 | 9 | 10 | 12 | 14 | 15 | 20 |

| XH | 13 | 14 | 15 | 18 | 20 | 23 | 30 |

| HTD 5M | 5 | 6 | 6 | 8 | 9 | 10 | 12 |

| HTD 8M | 6 | 8 | 9 | 10 | 12 | 14 | 15 |

| HTD 14M | - | 10 | 12 | 13 | 15 | 18 | 20 |

In the table, the recommended maximum cam thickness (t) is listed according to the number of teeth on the sprocket.

Maximum cam thickness in mm when welded on opposite gap between teeth

Number of teeth on sprocket

| Typ | 20 | 25 | 30 | 40 | 50 | 60 | 100 |

| T 5 | 2 | 2 | 3 | 4 | 6 | 8 | 10 |

| T 10 | 3 | 4 | 4 | 6 | 9 | 12 | 20 |

| T 20 | 5 | 5 | 6 | 8 | 12 | 20 | 30 |

| AT 5 | 2 | 2 | 3 | 4 | 6 | 8 | 10 |

| AT 10 | 3 | 4 | 4 | 6 | 9 | 12 | 20 |

| AT 20 | 5 | 5 | 6 | 8 | 12 | 20 | 30 |

| XL | 2 | 2 | 3 | 4 | 6 | 8 | 10 |

| L | 3 | 3 | 4 | 5 | 7 | 10 | 16 |

| H | 4 | 5 | 6 | 7 | 9 | 12 | 20 |

| XH | 2 | 5 | 6 | 8 | 12 | 20 | 30 |

| HTD 5M | 2 | 2 | 3 | 4 | 6 | 8 | 10 |

| HTD 8M | 3 | 3 | 4 | 4 | 6 | 9 | 12 |

| HTD 14M | - | 5 | 6 | 6 | 7 | 10 | 13 |

In the table, the recommended maximum cam thickness (t) is listed according to the number of teeth on the sprocket.