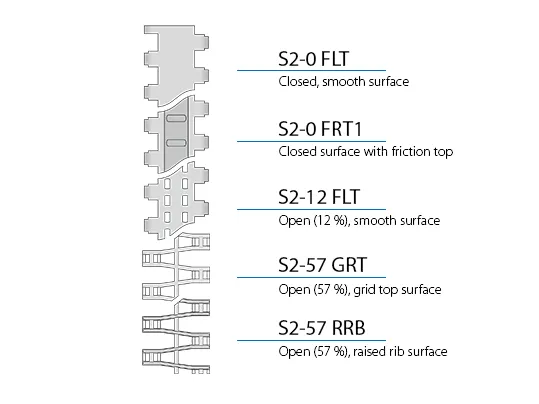

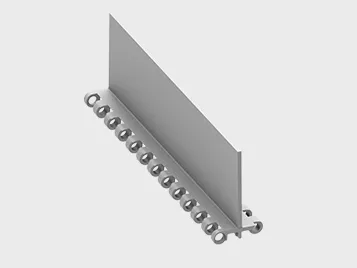

Design characteristics

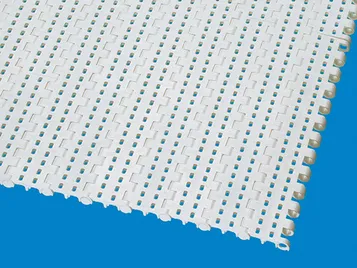

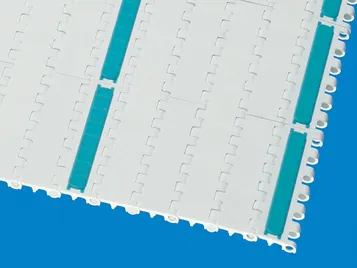

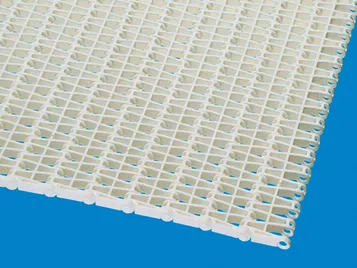

- Hinges that open wide provides an easy-to-clean belt design

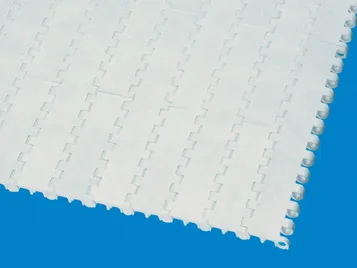

- Low belt weight reduces energy consumption

- Open edge design on flat top versions for unhindered drainage and closed edge design on grid top and raised rib versions

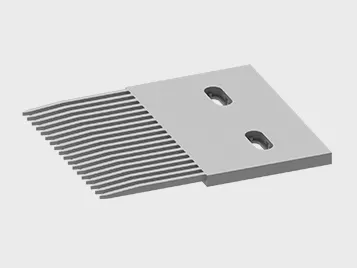

Straight running belts l Pitch 25 mm (0.98 in)

Belts for light-duty food and container handling applications

| Pitch | 25 mm (0.98 in) |

| Belt width min. | 50 mm (1.97 in) |

| 100 mm (3.9 in) for belts with FRT-pattern | |

| Width increments | 16.66 mm (0.7 in) |

| Hinge pins | Made of plastic (PE, PP, PBT) |

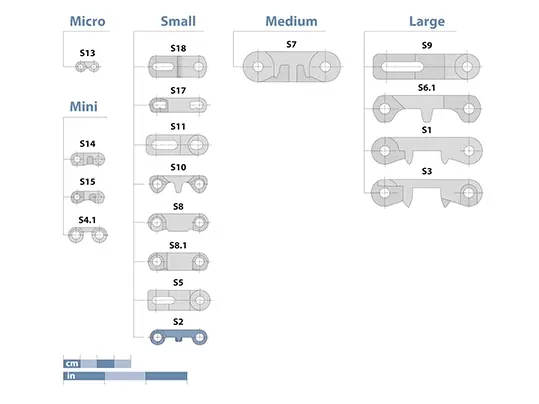

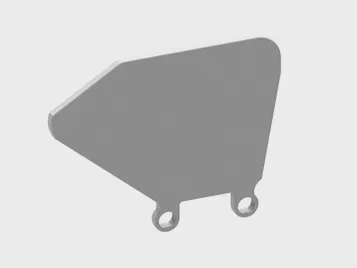

In different sizes with round or square sprocket bore

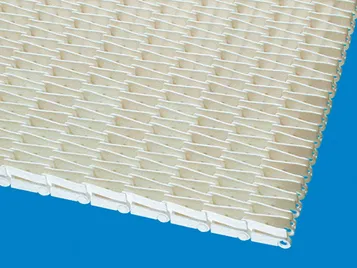

In different heights and designs for inclines

In different heights for retention of bulk products

For raised rib types