Creating better environments

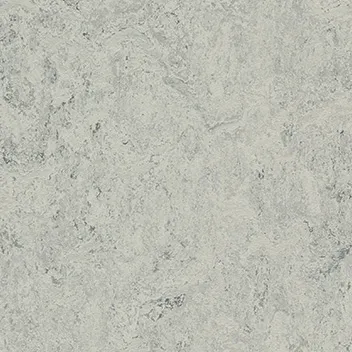

With Marmoleum, you choose a sustainable floor that is climate positive (cradle to gate). From the origins to the final product, without buying carbon credits.

The raw materials used for creating Marmoleum are rapidly renewable and have absorbed such an amount of CO2 during the time the plants, trees and crops have grown, that this amount of CO2 exceeds the amount of CO2 that is emitted during the production process of linoleum. Our Marmoleum is produced in a modern, energy efficient environment. We produce with 100% green electricity derived from the sun and wind, not adding any CO2.

All this results in a climate positive, natural, circular floor covering product.

Thanks to its biobased raw materials and continuous life cycle improvements, every square meter of our Marmoleum flooring made from cradle to gate removes 446 grams of carbon dioxide from the atmosphere, without offsetting.

Marmoleum fits into any sustainable interior. We have a choice: by using durable materials in our homes, offices, schools, trains, hospitals and shops, we can create better environments!

Find out more about the sustainable nature of Marmoleum.