Adhesives & Copper Strip

641 Eurostar Special EL

Very low VOC-emission conductive adhesive with a high initial grab for the installation of conductive carpet, conductive PVC floor covering in sheets and tiles and conductive rubber floor covering in sheets and tiles with a smooth back. Solvent-free, non-flammable, easy and safe to apply, multi-purpose application, high initial adhesion strength, favourable spreading capacity, roller-castor-chair resistant, electrical resistance < 3*105 Ohm (EN 13 415). For optimal conductivity apply with 801 Copper strip.

Suitable for: Colorex SD/EC and Sphera SD/EC

641 Eurostar Special EC Safety Data sheet

641 EUROSTAR SPECIAL EL technical specifications

641 Eurostar Special EL Tvoc emissions test certificate

| Basis | Superior acrylic dispersion |

| Packaging | 10 litres (12 kg) |

| Approx. coverage | up to 42 m²* |

| Shelf life | 12 months, unopened |

*Coverage rates will vary depending on the nature and porosity of the substrate.

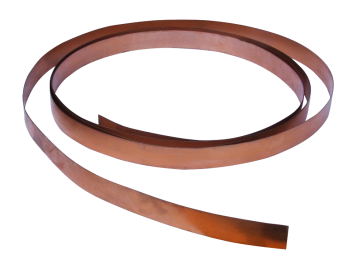

801 Eurostrip

Self-adhesive copper strip, use when installing a conductive floor covering. Ensures transverse potential equalisation.

801 Eurostrip Technical Specifications

| Basis | Electrolyte copper strip |

| Dimensions | Length 20 m. Width 10 mm |

| Thickness | 0,1 mm |

Welding Rods

Colorex welding rods

Colorex tiles and all the accessories on this page can be welded with Colorex welding rod, which is available in colours to match the main Colorex tile.

| Order Unit: | 1 pack (2 coils per pack) |

| Size: | 1 pce = 4mm diameter x 50lm coil |

Vinylweld

After installation, Forbo's vinyl floorings can be hot-welded for functional, decorative and/or hygienic reasons. Forbo vinyl welds are available in a variety of colours and are suitable for Sphera SD/EC.

| Order Unit: | 1 pce = 50 lm reel |

| Colours: | Multiple |