Vi går den grønne vej

Naturlige råvarer

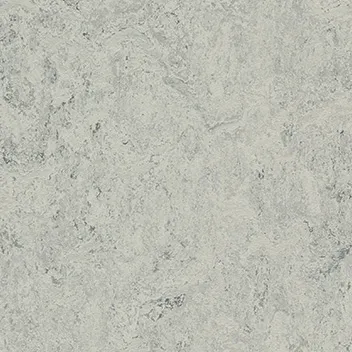

Marmoleum er et naturligt gulv fremstillet af 97% naturlige råvarer, 70% som er vedvarende, sammen med 43% genbrugsmateriale. De vigtigste råvarer, der anvendes i produktionen omfatter linolie, som kommer fra hør plantefrø, træmel som produktionsaffald fra kontrollerede skovbrugsplantager og jute, det naturlige bærervæv, som udgør bagsiden af linoleum.

Naturlig habitat

Hvad der gør Marmoleum specielt, er, at det er skabt udelukkende af råmaterialer fra deres naturlige habitat, hvor de vokser og fornyes, ofte på bare 12 måneder. Jute og hør er årlige afgrøder, der kan høstes ligesom hvede eller majs. Uddragning af kolofonium er en kontinuerlig proces, mens træmel, et affaldsmateriale fra træindustrien, der stammer fra europæiske produktionskove. Kalksten er tilgængelig i overflod.

Nedbrydes biologisk

Alt dette gør Marmoleum til et naturligt gulvbelægning, som efter en lang livscyklus på 30 plus år kan starte helt igen. Marmoleum kan kasseres, da det er bionedbrydeligt. Alternativt leverer styret forbrænding af Marmoleum et højere kalorieindhold og skaber termisk energi, som opvejer den energi, der anvendes under produktionen. Dette demonstrerer den fulde livscykluscirkel, hvorfra naturen i sidste ende gavner.